Utilization of pharmaceutical agents like antibiotics can lead to cardiotoxicity, a clinical condition that compromises the heart’s ability to function normally. The left ventricle’s contractile capacity is weakened, possibly prompting cardiovascular breakdown—a serious clinical result. An engineered heart that allows for early monitoring of drug-induced cardiotoxicity was recently successfully created by POSTECH and Georgia Institute of Technology researchers using 3D printing technology.

An engineered heart model using biohybrid 3D printing that enables in vitro monitoring of drug-induced cardiotoxicity in their research has been produced by the team at POSTECH, which is led by Professor Jinah Jang (Department of Mechanical Engineering and the Department of Convergence IT Engineering), Donghwan Kim (School of Interdisciplinary Bioscience and Bioengineering), Wan Kyun Chung and Professor Keehoon Kim (Department of Mechanical Engineering), and Professor Unyong Kim

In Advanced Materials, the research findings on drug-induced cardiotoxicity that detail wireless, real-time, and continuous monitoring are featured.

“Our biohybrid 3D printing approach employed to produce the tissue-sensor platform has the potential to advance drug development, representing a significant step toward the fabrication of next-generation tissue-sensor platforms,”

Professor Jinah Jang from POSTECH.

During the early stages of drug development, cardiotoxicity caused by the drug is thought to be a major obstacle. The majority of conventional heart models lack physiological relevance and are less able to predict the cardiotoxic potential of drugs, despite the availability of numerous in vitro platforms for preclinical cardiotoxicity testing. A number of researchers have utilized 3D-engineered heart tissue (EHT) in their study of myocardial contraction and pharmacological effects as a promising alternative that mimics the physiological contraction of the heart. However, a barrier remains in the absence of a suitable platform for continuous in vitro monitoring to examine the acute and chronic effects of pharmaceuticals.

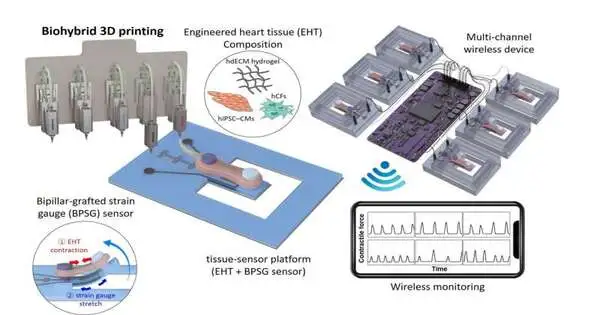

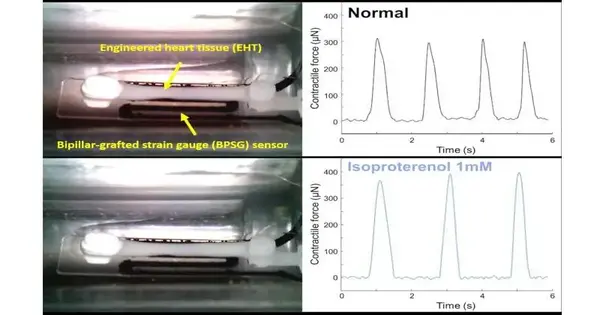

Biohybrid 3D printing was chosen by the research team as a method of engineering a heart model that was superior to conventional models. A platform that combined EHT and a bipillar-grafted strain gauge (BPSG) sensor was created by the group. Two pillars were printed in three dimensions and then grafted onto a substrate with strain gauges embedded in it as part of their strategy. After it was manufactured, the EHT was incorporated into the BPSG sensor to make a tissue-sensor stage prepared to do ongoing observing of heart compressions. The team successfully demonstrated this platform’s usefulness in testing drug-induced acute and chronic cardiotoxicity by successfully combining it with a multichannel wireless device to enable continuous monitoring of EHT contractions.

The ability of traditional in vitro monitoring systems to process large volumes of image-based data over extended periods with high temporal resolution for heart models has been limited. However, the research team’s tissue-sensor platform enables long-term and continuous monitoring by making it possible to quantitatively measure contractile force with a relatively small electrical readout volume.

“This biohybrid 3D printing strategy used to make the tissue-sensor stage has the potential in propelling medication improvement, addressing a basic step towards the assembling of cutting edge tissue-sensor stage,” said Teacher Jinah Jang from POSTECH.

More information: Uijung Yong et al, Biohybrid 3D Printing of a Tissue‐Sensor Platform for Wireless, Real‐Time, and Continuous Monitoring of Drug‐Induced Cardiotoxicity, Advanced Materials (2022). DOI: 10.1002/adma.202208983