Another MIT-created heat treatment changes the tiny design of 3D-printed metals, making the materials more grounded and stronger in outrageously warm conditions. The method could enable 3D printing of elite execution edges and vanes for power-creating gas turbines and fly motors, enabling new plans with improved fuel utilization and energy proficiency.

The present gas turbine edges are made through regular projecting cycles in which liquid metal is filled into complex molds and directionally set. These parts are produced using the absolute highest-intensity safe metal amalgams on the planet, as they are intended to turn at high rates in very hot gas, removing the need to create power in power plants and push in flywheel motors.

There is developing interest in assembling turbine edges through 3D-printing, which, notwithstanding its natural and money-saving advantages, could permit makers to rapidly create more complex, energy-effective edge calculations. Yet, endeavors to 3D-print turbine edges still can’t seem to clear a major obstacle: creep.

“The material begins as microscopic grains with imperfections known as dislocations that resemble tangled spaghetti. When this material is heated, the faults can be destroyed and reconfigured, allowing the grains to grow. Recrystallization is the process by which we continuously lengthen the grains by eating faulty material and smaller grains.”

Zachary Cordero, the Boeing Career Development Professor in Aeronautics and Astronautics at MIT.

In metallurgy, “creep” alludes to a metal’s propensity to twist despite steady mechanical pressure and high temperatures. While scientists have investigated printing turbine edges, they have found that the printing system creates fine grains on the order of tens of microns in size—a microstructure that is particularly helpless against creep.

“By and by, this would mean a gas turbine would have a more limited life or be less eco-friendly,” says Zachary Cordero, the Boeing Vocation Improvement Teacher in Flying and Astronautics at MIT. “These are expensive, unwanted results.”

Cordero and his partners figured out how to work on the design of 3D-printed compounds by adding an extra intensity treating step, which changes the as-printed material’s fine grains into a lot bigger “columnar” grains—aa sturdier microstructure that ought to limit the material’s drag potential, since the “segments” are lined up with the hub of most prominent pressure. The analysts say the strategy, framed today in “added substance assembly,” paves the way for modern 3D-printing free from gas turbine edges.

“Soon, we imagine gas turbine makers will print their edges and vanes at large-scale added substance producing plants, then post-process them utilizing our intensity therapy,” Cordero says. “3D printing will enable new cooling models that can work on the warm proficiency of a turbine, creating a comparable measure of force while consuming less fuel and, ultimately, emitting less carbon dioxide.”

Cordero’s co-creators on the review are lead creator Dominic Peachey, Christopher Carter, and Andres Garcia-Jimenez at MIT, Anugrahaprada Mukundan and Marie-Agathe Charpagne of the College of Illinois at Urbana-Champaign, and Donovan Leonard of Oak Edge Public Lab.

Setting off a change

The group’s new strategy is a type of directional recrystallization—aan intensity therapy that takes a material through a hot zone at an exactly controlled speed to merge a material’s numerous tiny grains into bigger, sturdier, and more uniform gems.

Directional recrystallization was invented many years ago and has since been applied to fabricated materials.In their new review, the MIT group adjusted directional recrystallization for 3D-printed superalloys.

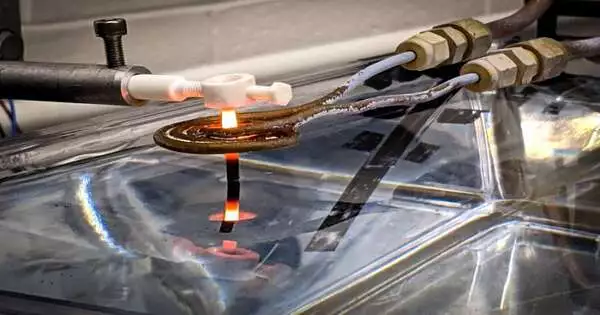

The group tried the strategy on 3D-printed nickel-based superalloys—mmetals that are commonly projected and utilized in gas turbines. In a progression of tests, the scientists set 3D-printed samples of bar-formed superalloys in a room-temperature water shower put just under an enlistment loop. They gradually coaxed every bar out of the water and through the loop at different paces, decisively warming the poles to temperatures changing somewhere in the range of 1,200 and 1,245 degrees Celsius.

They discovered that drawing the bars at a specific speed (2.5 millimeters per hour) and temperature (1,235 degrees Celsius) produced a lofty, warm slope that caused a change in the printed, fine-grained microstructure of the material.

“The material starts as small grains with deserts called separations that look like ruined spaghetti,” Cordero explains.”At the point when you heat this material up, those deformities can destroy and reconfigure, and the grains can develop.” We’re constantly extending the grains by consuming the flawed material and more modest grains—a cycle named recrystallization.

Creep away

Subsequent to cooling the intensity-treated bars, the analysts analyzed their microstructure utilizing optical and electron microscopy and observed that the material’s printed tiny grains were supplanted with “columnar” grains, or long gem-like areas that were altogether bigger than the first grains.

“We’ve totally changed the design,” says lead creator Dominic Peachey. “We show we can build the grain size by significant degrees, to huge columnar grains, which hypothetically ought to prompt emotional upgrades in creep properties.”

The group likewise showed they could control the draw speed and temperature of the bar tests to tailor the material’s developing grains, making areas of explicit grain size and direction. According to this degree of control, Cordero can empower makers to print turbine edges with site-explicit microstructures that are strong under explicit working circumstances.

Cordero plans to test the intensity therapy on 3D-printed calculations that more intently look like turbine edges. The group is likewise investigating ways of accelerating the draw rate as well as testing an intensity-offered design’s resistance to creep. Then, they imagine that the intensity therapy could empower the useful use of 3D printing to create modern-grade turbine edges, with additional intricate shapes and examples.

“New edge and vane calculations will empower more energy-effective land-based gas turbines, as well as, at last, aeroengines,” Cordero notes. “This could, according to a gauge viewpoint, lead to bringing down carbon dioxide outflows simply through better proficiency with these gadgets.”

More information: Dominic D.R. Peachey et al, Directional recrystallization of an additively manufactured Ni-base superalloy, Additive Manufacturing (2022). DOI: 10.1016/j.addma.2022.103198