Because it frequently involves a number of steps and analyses, designing dependable aircraft can be difficult and time-consuming. By assisting developers in identifying the most promising solutions or potential flaws with a specific aircraft, deep learning models have the potential to speed up the design and deployment of aircraft.

Researchers would require extensive datasets containing a wide variety of designs for aerial vehicles in order to train these models. However, because many designs are protected by proprietary contracts or are difficult to source, compiling these datasets can be challenging.

AircraftVerse, a massive dataset containing thousands of aircraft designs of varying complexity, was recently created by Vanderbilt University, SRI International, and the Southwest Research Institute. Their dataset, introduced in a paper pre-distributed on arXiv, could be utilized to prepare AI to help ethereal vehicle planners.

“Scientific analytical and simulation models, such as computer-aided design tools for structural and manufacturing analysis, computational fluid dynamics tools for drag and lift computation, battery models for energy estimation, and simulation models for flight control and dynamics, are required for the evaluation of these cyber-physical system (CPS) designs.”

Adam D. Cobb, Anirban Roy and their colleagues wrote in their paper.

Adam D. Cobb, Anirban Roy, and their colleagues wrote in their paper, “Aircraft design encompasses different physics domains and, therefore, multiple modalities of representation.” Scientific analytical and simulation models, such as computer-aided design (CAD) tools for structural and manufacturing analysis, computational fluid dynamics (CFD) tools for drag and lift computation, battery models for energy estimation, and simulation models for flight control and dynamics, are required for the evaluation of these cyber-physical system (CPS) designs.”

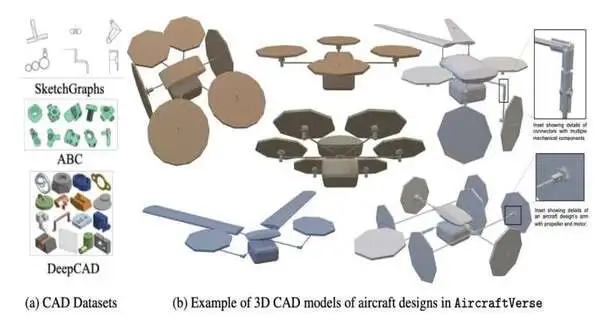

The SketchGraphs, DeepCAD, and ABC datasets, which are used to train machine learning for computer-aided design (CAD), mostly contain information about individual mechanical parts. On the other hand, Cobb, Roy, and their coworkers’ dataset includes fully functional aircraft designs that combine a variety of components like propellers, wings, motors, batteries, and so on.

Cobb, Roy, and their colleagues explained in their paper that “AircraftVerse contains 27,714 diverse air vehicle designs—the largest corpus of engineering designs with this level of complexity.”

“The following elements are found in each design: a symbolic design tree that describes topology, the battery subsystem, the propulsion subsystem, and other design details; a Product Exchange Standard (STEP) for model data; a stereolithography (STL) file format for a 3D CAD design; a 3D point cloud for the state of the plan; and evaluation results from cutting-edge, high-fidelity physics models that describe performance metrics like hover time and maximum flight distance.”

A deep learning-based method was used to create the designs in the AircraftVerse dataset, which were based on general rules provided by experienced aircraft designers. The researchers passed the final versions of these designs through engineering models, which resulted in the production of metadata that provided a synopsis of each design’s distinctive features and performance.

Cobb, Roy, and their coworkers wrote, “As part of our dataset release, we also present baseline surrogate models that use different modalities of design representation to predict design performance metrics.” Finally, we talk about how this dataset might affect how learning is used in aircraft design and CPS in general.”

The baseline models and underlying code for the brand-new dataset created by this team of researchers are now available to the general public online. As a result, it might soon be used by developers and designers all over the world to help them design and evaluate new aerial vehicles’ performance.

More information: Adam D. Cobb et al, AircraftVerse: A Large-Scale Multimodal Dataset of Aerial Vehicle Designs, arXiv (2023). DOI: 10.48550/arxiv.2306.05562