The disclosure that football players were unwittingly gaining super durable cerebrum harm as they piled up head hits all through their expert professions made a race to configure better head security. Nanofoam, which is used in football helmets, is one of these inventions.

Nanofoam and protective sports equipment have recently undergone a significant upgrade as a result of the work of the University of Virginia’s associate professor of mechanical and aerospace engineering, Baoxing Xu, and his research team. “Non-wetting ionized liquid,” a type of water that Xu and his research team now know perfectly blends with nanofoam to create a liquid cushion, is incorporated into this newly developed design. This flexible and responsive material will give better security to competitors and is promising for use in safeguarding vehicle tenants and helping clinic patients utilize wearable clinical gadgets.

The group’s exploration was, as of late, distributed in cutting-edge Materials.

A helmet’s protective foam between the inner and outer layers should be able to withstand multiple hits, game after game, for maximum safety. The material should be sufficiently cushiony to make a delicate spot for a head to land, yet strong enough to return and be prepared for the following blow. Additionally, the material must be resilient but not hard, as “hard” also hurts heads. Having one material do these things is a difficult task.

“We discovered that using ionized water instead of regular water to make a liquid nanofoam cushion made a significant difference in how the material performed. We discovered an unusual liquid-ion coordination network that allowed us to construct a more sophisticated material by using ionized water in the design.”

Aerospace engineering associate professor Baoxing Xu at the University of Virginia.

The team improved on earlier research that had been published in the Proceedings of the National Academy of Sciences and looked into how liquids could be used in nanofoam to create a material that could meet the stringent safety requirements of high-contact sports.

“We figured out that making a fluid nanofoam pad with ionized water rather than standard water had a tremendous effect on the manner in which the material performed,” Xu said. “We discovered an unusual liquid-ion coordination network, which made it possible to create a more sophisticated material, making the design’s use of ionized water a breakthrough.

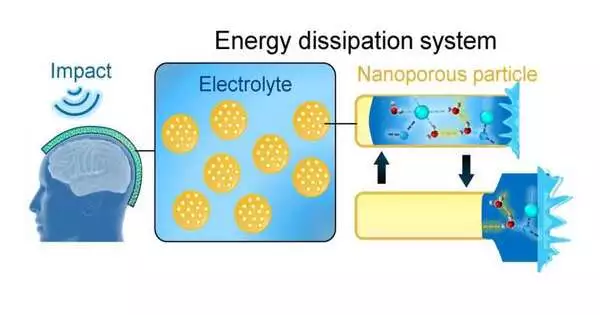

The helmet’s interior can be compressed and dispersed by the liquid nanofoam cushion, minimizing the force transmitted to the head and decreasing the likelihood of injury. It additionally recaptures its unique shape after influence, considering different hits and guaranteeing the cap’s viability in safeguarding the competitor’s head during the game.

“A special reward,” Xu proceeded, “is that the improved material is more adaptable and significantly more agreeable to wear. The material progressively answers outer shocks due to the manner in which the particle groups and organizations are created in the material.”

“The fluid pad can be planned as lighter, more modest, and more secure defensive gadgets,” said academic administrator Weiyi Lu, a partner in structural design at Michigan State College. “Likewise, the decreased weight and size of the fluid nanofoam liners will alter the plan of the hard shell of future caps. One day, you might be watching a football game and wondering how the players’ heads are protected by the smaller helmets. It very well may be a result of our new material.”

The protection mechanism of conventional nanofoam is based on material properties that respond to mechanical deformation or crunching, such as “collapse” and “densification.” Breakdown is what it seems like, and densification is the serious misshapening of frothy areas of strength. After the breakdown and densification, the conventional nanofoam doesn’t recuperate very well due to the super-durable deformity of materials, making the security a one-time bargain. When contrasted with the fluid nanofoam, these properties are extremely sluggish (a couple of milliseconds) and can’t oblige the “high-force decrease prerequisite,” and that implies it can’t really retain and disseminate high-force blows in the brief time frame related to crashes and effects.

Another drawback of conventional nanofoam is that it becomes completely “hard” and behaves like a rigid body that cannot provide protection when subjected to multiple small impacts that do not deform the material. The rigidity has the potential to cause soft tissue damage and injuries like traumatic brain injuries (TBI).

By controlling the mechanical properties of materials—coordinating nonporous materials with “non-wetting fluid” or ionized water—the group fostered a method for making a material that could answer influences in a couple of microseconds since this blend is considered a superfast fluid vehicle in a nanoconfined climate. Additionally, the liquid nanofoam cushion can return to its original form upon unloading or after impacts due to its non-wetting nature. This is because the liquid is ejected out of the pores, allowing it to withstand repeated blows. This dynamic adjusting and changing skill likewise cures the issue of the material becoming inflexible from miniature effects.

The very fluid properties that make this new nanofoam more secure for sports equipment additionally offer a possible use in different spots where crashes occur, similar to vehicles, whose wellbeing and material defensive frameworks are being reevaluated to embrace the emergence of electric impetus and robotized vehicles. It can be used to make cushions that protect against accidents and help reduce noise and vibration.

The potential role that liquid nanofoam can play in the setting of a hospital is another reason that might not be as obvious. The froth can be utilized in wearable clinical gadgets like a smartwatch, which screens your pulse and other crucial signs. By integrating fluid nanofoam innovation, the watch can have a delicate and adaptable froth-like material on its underside and assist with working on the precision of the sensors by guaranteeing legitimate contact with your skin. It can adjust to the state of your wrist, making it comfortable to wear day in and day out. As a shock absorber, the foam can also provide additional protection. On the off chance that you unintentionally knock your wrist against a hard surface, the froth can assist with padding the effect and forestall any damage to the sensors or your skin.

More information: Yuan Gao et al, Nanoconfined Water‐Ion Coordination Network for Flexible Energy Dissipation Device, Advanced Materials (2023). DOI: 10.1002/adma.202303759