Wearable technologies, biosensors, medical implants, and soft robots are just a few examples of the increasingly smaller and more advanced devices that have been made possible by recent advancements in electronics. Stretchy materials with electronic properties serve as the foundation for most of these technologies.

Although a wide range of flexible materials that could be used to make electronics have already been developed by material scientists, many of these materials are fragile and easy to break. Several existing soft and conductive materials can become unreliable and unsuitable for large-scale implementations because damage to them can result in their failure and compromise the system’s overall operation.

A new hydrogel that is self-healing and conductive was recently developed by researchers at Harbin University of Science and Technology in China. This hydrogel has the potential to be used to create flexible sensors for wearables, robots, and other devices. The Journal of Science provided an overview of this material and its composition: Advanced tools and materials.

“In this study, a flexible sensor with remarkable self-healing performance was assembled using polyaniline (PANI), 4-carboxylbenzaldehyde (4-CBA), and polyvinyl alcohol (PVA) as a double network skeleton.”

Xiaoming Wang, Ling Weng and their colleagues wrote in their paper.

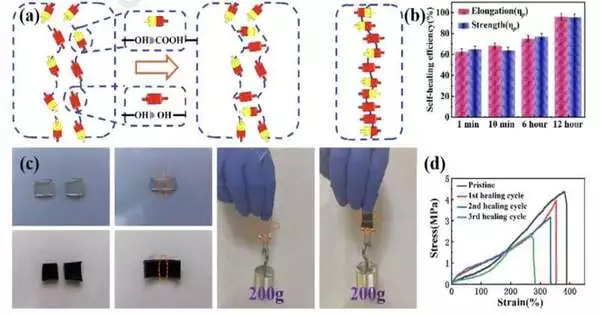

In their paper, Xiaoming Wang, Ling Weng, and their colleagues wrote, “In this paper, polyvinyl alcohol (PVA) and 4-carboxylbenzaldehyde (CBA) were used to form a double network skeleton, and polyaniline (PANI) was introduced to assemble a flexible sensor with excellent self-healing performance.” The hydrophobic relationship of PVA and CBA ensures the mechanical properties of the hydrogel sensor, and the presentation of PANI carries electrical properties to the hydrogel sensor.”

By electrostatically combining the conducting polymer PANI with CBA, an organic compound composed of a benzene ring substituted with an aldehyde and carboxylic acid, Wang, Weng, and their coworkers were able to create their material. They discovered during the initial tests that the material had remarkable mechanical properties and was capable of self-healing after being damaged. Besides, it could arrive at a maximum pressure of 4.35 Mpa and a most extreme type of 380%.

The scientists then utilized the material to make a strain sensor, a detecting gadget that can identify outside powers and apply pressure starting from its environmental elements. This sensor was found to be very effective at detecting both subtle signals of deformation, such as a wearer coughing or speaking, and more forceful body movements.

In their paper, Wang, Weng, and their colleagues wrote, “The flexible sensor prepared in this article has a sensitivity of 1.71 in the strain range of 0–300% and a limit detection strain of less than 1%.” The hydrogel sensor has a response time of 158 milliseconds when stretched. What’s more, the hydrogel sensor likewise has self-mending execution. The repair can be completed in one minute at room temperature after the hydrogel is cut, and the self-healing rate is about 60%.”

The hydrogel that this group of researchers made could be used to make a wide range of other sensors and wearable electronics in the future. For instance, sensors that can detect human motion or medical devices that look for specific biological signals could be made using this hydrogel. In addition, their work may open the door to the creation of self-healing hydrogels that are similarly flexible and conductive.

More information: Xiaoming Wang et al, Constructing conductive and mechanical strength self-healing hydrogel for flexible sensor, Journal of Science: Advanced Materials and Devices (2023). DOI: 10.1016/j.jsamd.2023.100563