Wearable gadgets, from wellness and wellness trackers to augmented reality headsets, are essential for our daily existences. Yet, tracking down approaches to constantly driving these gadgets is a test.

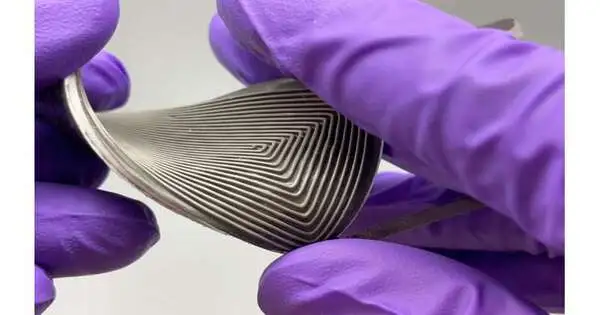

College of Washington scientists have fostered a creative arrangement: the first-of-its-kind adaptable, wearable thermoelectric gadget that converts body intensity to power. This gadget is delicate and stretchable yet solid and effective—properties that can be hard to combine.

The group published these discoveries on July 24 in Advanced Energy Materials.

“While answering basic scientific problems, we use additive manufacturing to build stretchy electronics, boost their efficiency, and enable their seamless integration into wearables.”

Mohammad Malakooti, a UW assistant professor of mechanical engineering.

“It’s a 100 percent gain assuming we harvest nuclear power that would otherwise be lost due to environmental factors.””Since we need to use that energy for self-fueled gadgets, a more powerful thickness is required,” said Mohammad Malakooti, a UW partner teacher of mechanical design. “We influence added substance assembling to create stretchable gadgets, increase their proficiency, and empower their consistent mix into wearables while addressing key examination questions.”

Indeed, even after in excess of 15,000 extending cycles at 30% strain, the scientists’ model gadget remains completely useful, a profoundly helpful component for wearable hardware and delicate mechanical technology. The gadget likewise shows a 6.5-times increase in power thickness compared with past stretchable thermoelectric generators.

To make these adaptable gadgets, the analysts 3D printed composites with designed primary and useful properties at each layer. The filler material contained fluid metal amalgams, which give high electrical and thermal conductivity. These compounds address limits in past gadgets, including a failure to extend, wasteful intensity, and a perplexing creation process.

The group also inserted empty microspheres to guide the intensity to the semiconductors at the center layer and lessen the heaviness of the gadget.

The analysts demonstrated the way that they could print these gadgets on stretchable material textures and bended surfaces, which suggests that future gadgets could be applied to clothing and different items. The group is amped up for the future prospects and genuine uses of wearable gadgets.

“One novel part of our exploration is that it covers the entire range, as far as possible, from material blend to gadget creation and portrayal,” said Malakooti, who is likewise a scientist in the UW’s Institute for Nano-Engineered Systems. “This gives us the opportunity to plan new materials, engineer each move toward the cycle, and be inventive.”

Youngshang Han, a UW expert’s understudy in mechanical design, was the lead creator of the paper. Leif-Erik Simonsen is an extra co-creator.

More information: Youngshang Han et al, Printing Liquid Metal Elastomer Composites for High‐Performance Stretchable Thermoelectric Generators, Advanced Energy Materials (2022). DOI: 10.1002/aenm.202201413

Journal information: Advanced Energy Materials