A strategy that has been developed by researchers at the Max Planck Institute for Colloids and Interfaces (MPICI) has the potential to make it harder to counterfeit goods in the future. Unique, non-copyable fluorescent patterns can now be produced quickly, sustainably, and affordably using a newly developed and patented method.

Every year, counterfeiting of medicines, certificates, or electronics results in global economic losses of billions of dollars. The World Wellbeing Association (WHO) estimates that fake prescriptions represent 73 billion euros in yearly deals. The World Health Organization (WHO) estimates that unauthorized online mail-order businesses account for half of all counterfeit medicines. Since 2019, medicine packaging in the EU has been marked with security features to combat this. Most counterfeit detection materials today, like fluorescent holograms, are made of toxic inorganic parts. Furthermore, a large portion of these strategies can be duplicated in the span of a year and a half of translating the fluorescent compound.

The group led by Dr. Felix Löffler from the Division of Biomolecular Frameworks has thought of a totally new way to deal with non-copyable nanopatterns in a paper distributed in the journal Nature Nanotechnology.

“The exciting thing about this is that you can create any pattern you want, as we demonstrated with the example of artificial fingerprints. The micro- and nanostructures that result are completely random. We won’t be able to manage them; there will be no pattern.”

Junfang Zhang, first author of the study,

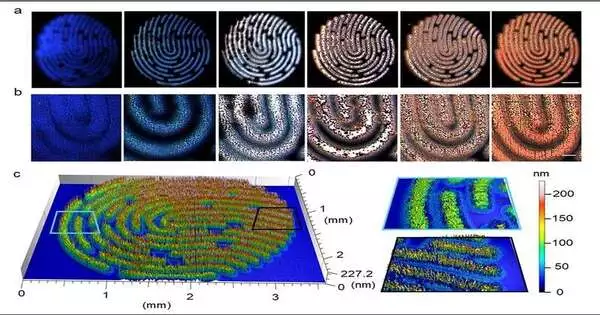

Initial, a slight sugar film comprising basic monosaccharides is besieged with a laser. In this blaze combination, the sugar “caramelizes” in milliseconds, and simultaneously, the laser prints irregular “caramel examples” on an ideal surface. Under the scanner, these are one-of-a-kind and fluoresce in a variety of colors.

“The exciting thing here is that you can create any pattern you want, which we have shown using the example of artificial fingerprints,” says Junfang Zhang, the study’s first author. The micro- and nanostructures that are produced are completely arbitrary. They are beyond our control; no pattern will emerge.” Dr. Felix Löffler adds: “We obtain unique color gradations of red, green, or blue based on the laser parameters and additives for each sugar pattern.

In their tests, the group made a nanofilm library of around 2,000 nanopatterns. Fluorescence scanning and topography scanning are the two scanning techniques that can be used to quickly and independently read the microstructure of these sugar patterns, which cannot be copied. The two techniques exhibit practically ideal piece correspondence, high uniqueness, and dependability in the examples created.

This indicates that the patterns are extremely random, which is crucial for their function as copy protection. The blend of the two techniques works on the insurance against duplication (PUF = genuinely unclonable capability). ” Additionally, we can generate up to 10 to the power of 63,000 distinct variants on 1 mm2 using our method. Dr. Felix Löffler, who is in charge of the group, says, “For a comparison, the number of atoms in the universe is about 10 to the power of 89.”

More information: Junfang Zhang et al, An all-in-one nanoprinting approach for the synthesis of a nanofilm library for unclonable anti-counterfeiting applications, Nature Nanotechnology (2023). DOI: 10.1038/s41565-023-01405-3