Scientists have created a fully functional standalone solar-powered mini-reactor that could be used to produce fine chemicals in remote locations on Earth, and possibly even Mars. Professor Timothy Nol and colleagues at the University of Amsterdam’s Van ‘t Hoff Institute for Molecular Sciences have developed a fully operational standalone solar-powered mini-reactor that could be used to produce fine chemicals in remote locations on Earth, and possibly even Mars. The team describes their unique, fully off-grid photochemistry system in a paper published by ChemSusChem.

According to Professor Nol, the new system, which is capable of synthesizing drugs and other chemicals in economically relevant volumes, ‘shines in isolated environments and allows for the decentralization of fine chemical production.’ The mini-plant is based on the photochemistry concept, which uses sunlight to directly ‘power’ chemical synthesis.

‘We use a photocatalyst, which is a chemical species that drives synthesis when it is illuminated,’ Nol continues. ‘Normally, powerful LEDs or other lighting equipment are used for illumination, but we chose sunlight.’ To begin with, this makes the synthesis completely sustainable. However, it also allows for stand-alone operation in remote locations. Our ambition is to see our system used at a base on the Moon or Mars, where self-sustaining systems for energy, food, and medicine are required. Our mini-plant could contribute to this in a completely autonomous and self-sufficient manner.’

The new system, which is capable of synthesizing drugs and other chemicals in economically relevant volumes, ‘shines in isolated environments and allows for the decentralization of fine chemical production.’ The mini-plant is based on the photochemistry concept, which uses sunlight to directly ‘power’ chemical synthesis.

Professor Timothy Nol

A solar-driven flow reactor

The mini-development plants began around five years ago, when the Nol research group, which was based at Eindhoven University of Technology at the time, developed a ‘solar concentrator.’ This is essentially a sheet of clear plastic with micrometer-sized channels through which the chemical synthesis occurs. The researchers transformed the plastic into a solar guide and luminescent converter by adding specific dyes. It captures sunlight and directs it toward the channels, converting a significant portion of it into red photons that drive the chemical conversion.

The concentrator was then converted into a fully operational flow reactor. ‘We pump a reaction mixture of starting materials and photocatalyst through the sunlit channels,’ explains Nol. ‘The desired chemical conversion occurs in these channels, making them our alternative to traditional chemical synthesis flasks or vessels.’ Nol goes on to explain that, despite the fact that the channels are quite small, such a ‘flow reactor’ can produce quite relevant outputs because it operates continuously from sunrise to sunset. ‘What’s more,’ he adds, ‘the use of channels allows for a far more effective coupling between light and chemistry than is possible when using traditional flask reactors.’

Maximum efficiency

The Nol research group had previously demonstrated the solar flow reactor concept by synthesizing a variety of medicinally relevant molecules on a laboratory scale in a controlled environment. Now, in a recent paper published in ChemSusChem, they describe how they created a viable, optimally effective autonomous photosynthesis system and tested it in the field. They also forecast aspects like application potential and economic performance.

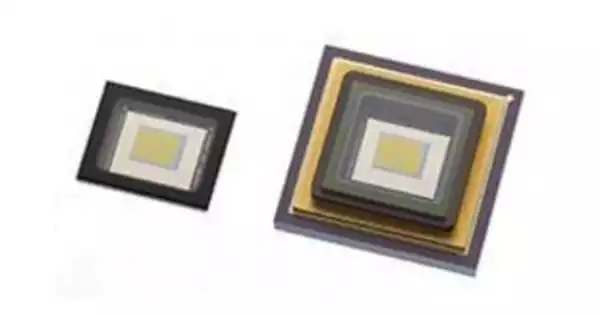

The prototype solar flow reactor now has a surface area of approximately 0.25 square meters. To make it fully self-sufficient, the researchers outfitted it with a solar cell that powers auxiliaries such as pumps and the control system. According to Nol, this solar cell is placed behind the flow reactor in a stacked configuration to ensure maximum efficiency per square centimetre. ‘In the reactor, the more energetic wavelengths are used to drive the photocatalyst. The remaining photons with wavelengths ranging from 600 to 1100 nm are converted to electricity and used to power the auxiliaries.’

Worldwide application potential

In addition, the fully autonomous prototype employs a responsive control system that can optimize chemical conversion at various light intensities. ‘Normally, when a cloud covers the sun, the chemical conversion would decrease very quickly,’ Nol says. ‘Our system is capable of making the required adjustments in real-time.’ Field tests confirmed that it can produce chemicals at a constant rate even on days that are partly sunny and partly cloudy.’ The tests were conducted in the Netherlands. To get a sense of the global deployment possibilities, solar data from Norway (North Cape), Spain (Almeria), and Australia were compared (Townsville). Noël: ‘Even at the North Cape, with relatively little sun power, we estimate satisfactory production figures.’

The researchers also compared the prototype system’s performance to figures for the well-known photochemical synthesis of rose oxide. Because a photochemical synthesis is cleaner and more efficient than traditional chemical synthesis, it is used in the perfume industry. The researchers calculated that their system would require a surprisingly small surface area to meet the current annual demand – just 150 m2.

‘That’s just one factory roof full of our mini-plants!’ says Nol. The cost of the system would be comparable to that of current commercial photosynthesis systems. However, we only require solar energy, so there are no energy costs. As a result, this could be a viable strategy for the future production of chemicals such as rose oxide or pharmaceuticals.’

Have the walls make chemicals

Nol believes that his group’s research dispels any doubts about the potential of solar-powered chemical technology: ‘We demonstrate that there are opportunities for solar-driven chemical production even here in the Netherlands.’ You don’t have to go to Qatar!’ Furthermore, the system lends itself to application in unexpected places. ‘You could even cover a building’s facade with it. Of course, the output would be lower than when the system is positioned at an optimal angle to the sun. But it’s certainly possible, and how cool would it be to have the walls produce chemicals?’