A new nanophotonic material has broken records for high-temperature soundness, possibly introducing more effective power creation and opening various additional opportunities in the control and change of warm radiation.

Created by a College of Michigan-driven group of compound and materials science designers, the material controls the progression of infrared radiation and is steady at temperatures of 2,000 degrees Fahrenheit in air, an almost twofold improvement over existing methodologies.

The material uses a peculiarity called damaging impedance to reflect infrared energy while allowing more limited frequencies to go through. This might actually decrease heat squander in thermophotovoltaic cells, which convert heat into power yet can’t utilize infrared energy, by reflecting infrared waves once again into the framework. The material may also be useful in optical photovoltaics, thermal imaging, natural boundary coatings, detection, protection from infrared reconnaissance devices, and other applications.

“It’s comparable to how butterfly wings gain their color through wave interference. Butterfly wings are constructed of colorless materials, but they are organized and arranged in such a way that some wavelengths of white light are absorbed while others are reflected, giving the appearance of color.”

Andrej Lenert, U-M assistant professor of chemical engineering

It’s like the manner in which butterfly wings use wave obstruction to get their variety. “Butterfly wings are comprised of dismal materials, yet those materials are organized and designed in a manner that retains a few frequencies of white light yet reflects others, creating the presence of variety,” said Andrej Lenert, U-M right-hand teacher of synthetic design and co-creator of the concentrate in Nature Nanotechnology.

“This material accomplishes something almost identical to infrared energy. The difficult aspect has been the forestalling breakdown of that tone-delivering structure under high intensity. “

The methodology is a significant takeoff from the present status of designed warm producers, which normally use froth and pottery to restrict infrared discharges. These materials are steady at high temperatures but offer extremely restricted command over which frequencies they let through. Nanophotonics could offer significantly more tunable control, yet past endeavors haven’t been steady at high temperatures, frequently dissolving or oxidizing (the cycle that structures rust on iron). Moreover, numerous nanophotonic materials just keep up with their steadiness in a vacuum.

The new material pursues taking care of that issue, outmaneuvering the past record for heat obstruction among air-stable photonic gems by in excess of 900 degrees Fahrenheit in outdoors. What’s more, the material is tunable, empowering scientists to change it to adjust energy for a wide assortment of expected applications. The exploration group anticipated that applying this material to existing TPVs will increment proficiency by 10% and accepts that a lot more noteworthy productivity acquires will be conceivable with additional streamlining.

The group fostered the arrangement by consolidating synthetic design and materials science ability. Lenert’s substance design group started by searching for materials that wouldn’t blend regardless of whether they began to soften.

“The objective is to find materials that will keep up with pleasant, fresh layers that mirror light in the manner that we need, in any event, when things get extremely hot,” Lenert said. “So we searched for materials with altogether different precious stone designs, since they tend not to need to blend.”

They guessed that a mix of rock salt and perovskite, a mineral made of calcium and titanium oxides, would fit the bill. Colleagues at U-M and the College of Virginia ran supercomputer recreations to affirm that the mix was a decent wager.

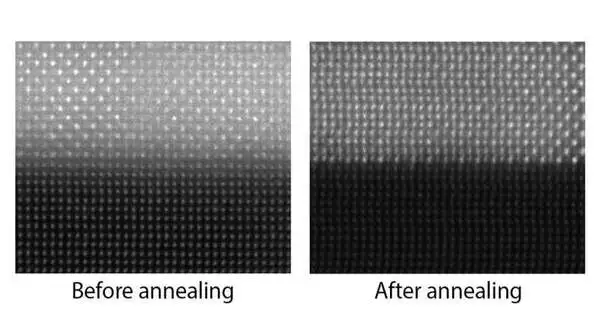

John Heron, co-relating creator of the review and an associate teacher of materials science and design at U-M, and Matthew Webb, a doctoral understudy in materials science and design, then painstakingly stored the material, utilizing beat laser testimony to accomplish exact layers with smooth connection points. To make the material considerably more solid, they utilized oxides as opposed to traditional photonic materials; the oxides can be layered all the more definitively and are less inclined to corrupt under high intensity.

“In past work, conventional materials oxidized under high intensity, losing their precise layered structure,” Heron said. “In any case, when you begin with oxides, that corruption has basically currently occurred. That produces expanded dependability in the last layered structure.

After testing affirmed that the material functioned as planned, Sean McSherry, the first creator of the review and a doctoral student in materials science and design at U-M, utilized PC demonstrating to distinguish many different blends of materials that are likewise liable to work. While commercialization of the material tested in the study is likely years away, the central discovery opens up another line of investigation into a variety of other nanophotonic materials that could end up being useful to future specialists in fostering a range of new materials for various applications.

More information: Sean McSherry et al, Nanophotonic control of thermal emission under extreme temperatures in air, Nature Nanotechnology (2022). DOI: 10.1038/s41565-022-01205-1

Journal information: Nature Nanotechnology