To handle an unnatural weather change, engineers have been attempting to foster progressively cutting-edge innovations that can create and store electrical energy more reasonably. The most famous among these advances are sun-powered cells, gadgets based on photovoltaic materials that can change sun-based radiation into power.

One material that has recently gotten a lot of attention for the advancement of solar cells is the safeguard bifacial Cu(In,Ga)Se2, also known as CIGS.This material could be especially encouraging for the making of slim film photovoltaics because of its eminent thermo-compound security.

In spite of their benefits, CIGS-based, sun-oriented cells frequently show unsuitable power change efficiencies, especially when tried in external lab settings. This severely limits their true potential, preventing them from being created and executed on a large scale.

“We avoided the development of GaOx by promoting low-temperature growth of the CIGS layer with silver. This procedure also improved the absorber quality, created a sharp Ga gradient near the back interface, and lowered the absorption of the transparent conducting oxide.”

Shih-Chi Yang and his colleagues wrote in their paper.

Scientists at the Swiss Government Labs for Materials Science and Innovation, Public Tsing Hua College, and College of Cantabria have as of late concocted a system that could assist with improving the power conversion efficiencies of CIGS slim film sun-based cells.

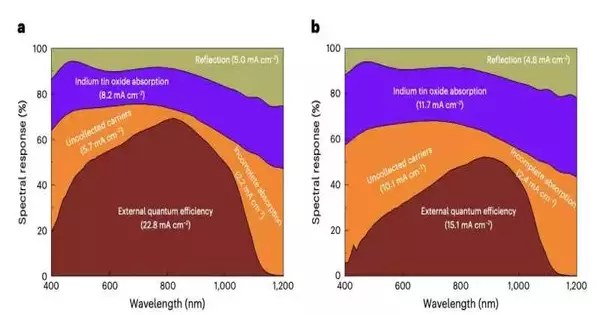

This system, presented in a paper distributed by Nature Energy, involves the utilization of a silver-aided low-temperature cycle to forestall the development of GaOx at the connection point between the CIGS layer and a straightforward leading oxide, which is known to hinder the cells’ exhibition.

“We forestalled the arrangement of GaOx by advancing the low-temperature development of the CIGS layer,” Shih-Chi Yang and his partners wrote in their paper. “This cycle also resulted in an improvement in the safeguard quality, a high Ga slope close to the back interface, and a decrease in the retention of the simple leading oxide.”

Basically, the scientists added a modest quantity of silver (4–5% AAC) to the CIGS safeguards, utilizing a low-temperature statement process. This cycle foreshadows the development of GaOx at the CIGS/ITO interface, settling issues commonly seen in CIGS-based solar cells.

To demonstrate the capability of this silver-aided low-temperature process, the scientists used it to create a progression of cells and then examined their performance in a trial setting.These underlying tests yielded extremely encouraging outcomes, as their system seemed to empower quite high power change efficiencies, which were generally more prominent than those of the other recently evolved CIGS cells that they were contrasted with.

“We likewise report an assured bifacial sun-based cell on a glass substrate with efficiencies of 19.77% and 10.89% under front and back light, separately,” Yang and his partners wrote in their paper. “We also created bifacial, sun-based cells directly on adaptable substrates.””Finally, we arranged bifacial perovskite and CIGS pair sun-based cells in a four-terminal configuration, achieving a power age thickness of 28.0 mW cm-2 under a single sun and 30% albedo light.”

Later, the new system devised by this team of analysts could pave the way for the commercialization and widespread use of CIGS solar cells. Also, their work could inspire different groups to foster comparable methodologies for working on the exhibition of slim film photovoltaics.

More information: Shih-Chi Yang et al, Efficiency boost of bifacial Cu(In,Ga)Se2 thin-film solar cells for flexible and tandem applications with silver-assisted low-temperature process, Nature Energy (2022). DOI: 10.1038/s41560-022-01157-9

Journal information: Nature Energy