Protonic ceramic electrochemical cells (PCECs) are emerging energy advances containing electrolytes in view of proton-leading oxides and oxygen-particle guides. These gadgets could contribute to the continuous shift towards maintainable energy arrangements by helping the worldwide creation of green hydrogen and electrical power.

PCECs enjoy various advantages over regular low-temperature electrochemical cells with polymer-based electrolytes. For example, they can achieve higher energy efficiencies and are viable with various kinds of fills.

Notwithstanding their great execution and invaluable qualities, these cells have so far demonstrated hard work to create and carry out a huge scope. The critical justification behind this is that their working temperature is incredibly high, commonly more than 500 °C.

“Reducing the operating temperature of PCEC can help with scale-up and commercialization. Obtaining excellent energy efficiency and long-term durability at low working temperatures, on the other hand, has long been a difficulty. We present a straightforward and scalable method for synthesizing ultrathin, chemically homogeneous, and resilient proton-conducting electrolytes, as well as a composite positive electrode generated in situ, Ba0.62Sr0.38CoO3-Pr1.44Ba0.11Sr0.45Co1.32Fe0.68O6.”

Fan Liu, Hao Deng and their colleagues wrote in their paper.

Scientists at Kansas State College, Colorado School of Mines, Nissan Specialized Center North America (NTCNA), Nissan Engine Organization, and the College of Oklahoma have recently presented another technique that cuts down the working temperatures of PCECs to below 450°C. Their proposed approach, presented in Nature Energy, could assist with beating the obstacles right now restricting the boundless utilization of these promising energy arrangements.

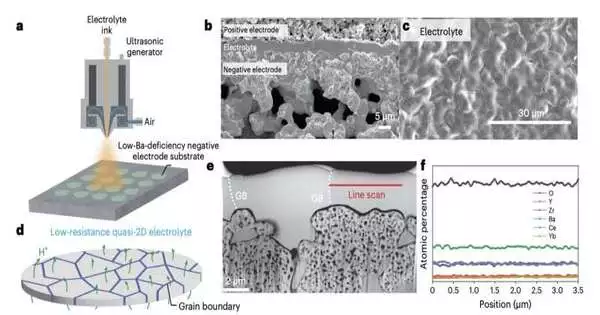

“Bringing down the PCEC working temperature can work with its scale-up and commercialization,” Fan Liu, Hao Deng, and their partners wrote in their paper. “Notwithstanding, achieving high energy productivity and long-haul strength at low working temperatures is a well-established challenge. We report a basic and versatile methodology for manufacturing ultrathin, synthetically homogeneous, and powerful proton-directing electrolytes and exhibit an in situ-shaped composite positive cathode, Ba0.62Sr0.38CoO3−δ-Pr1.44Ba0.11Sr0.45Co1.32Fe0.68O6−δ.”

The composite positive terminal made by the specialists can fundamentally diminish various kinds of opposition in PCECs, including ohmic obstruction and opposition connected to positive anode electrolyte contact and cathode polarization. Related to ideal electrolytes, this terminal could essentially work on the exhibition of PCECs at temperatures below 450°C.

To investigate the capability of their proposed plan systems, Liu, Deng, and their partners utilized them to make new PCECs. They then, at that point, ran a progression of tests to survey these gadgets’ power densities and working temperatures, both while they were filling in as energy units and as steam electrolyzers.

“The PCECs accomplish high power densities in energy unit mode (~0.75 W cm2 at 450 °C and ~0.10 W cm2 at 275 °C) and extraordinary current densities in steam electrolysis mode (−1.28 A cm2 at 1.4 V and 450 °C). At 600 °C, the PCECs achieve a power thickness of ~2 W cm−2,” Liu, Deng, and their partners wrote in their paper.

“Furthermore, we exhibit the immediate use of methane and alkali for power generation at <450 °C. Our PCECs are additionally steady for power generation and hydrogen creation at 400 °C.”

The consequences of the group’s underlying assessments are exceptionally encouraging, recommending that their proposed techniques could empower the creation of profoundly performing PCECs that can both act as power devices and support hydrogen creation, all while working at lower temperatures. Amazingly, the electrolyte made by the scientists was additionally found to empower protections equivalent to or even lower than those seen in recently evolved PCECs that depend on refined manufacturing processes.

The methodologies presented in this new paper could soon educate on the improvement of extra PCECs that can work at low temperatures, finally working with the huge scope organization of this arising energy arrangement. Later on, the group’s model cells could likewise be improved and culminated to additionally lessen their working temperatures and lift their presentation.

More information: Fan Liu et al, Lowering the operating temperature of protonic ceramic electrochemical cells to <450 °C, Nature Energy (2023). DOI: 10.1038/s41560-023-01350-4. www.nature.com/articles/s41560-023-01350-4