Researchers from the Department of Materials Science at the University of Tsukuba developed another strategy to deliver micrometer-scale single precious stones as empty vessels. By drop-projecting an ethanol arrangement onto a quartz substrate, the particles can suddenly gather into the legitimate shape. This exploration, published in Science, may pave the way for another line of tests in which compound cycles can be held inside these minute vessels.

Putting an extravagant bowl made of precious stone in a prominent spot in your home can establish a positive connection with your visitors. However, a much greater accomplishment would be the capacity to make such a vessel from a solitary tiny precious stone. While a few small life forms have been known to display this kind of mastery, it tends to be difficult for researchers to reproducibly make these nano-compartments on the grounds that uncontrolled development can prompt deformed end results.

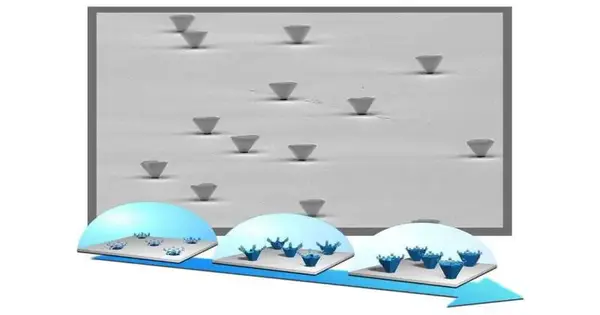

Presently, a group of scientists at the University of Tsukuba have revealed another methodology to reproducibly make empty vessel-molded precious stones that are uniform in size and joined to a substrate with their open side facing upwards. The gems were developed from particles that had a paracyclophane center and four (methoxyphenyl)ethynyl arms, called (S)-CP4, or its identical representation particle, (R)-CPP4. To deliver the containers, a warmed arrangement of (S)-CPP4 was delicately dropped onto a quartz substrate under encompassing circumstances. At the point when the arrangement cooled, the particles started to solidify suddenly. “Utilizing this system, we had the option to accomplish coordinated, uniaxial, and stepwise development of micrometer-sized single gems,” says senior creator Professor Yohei Yamamoto.

“Hollow crystals with complex morphologies and well-developed crystalline facets and edges can be incredibly helpful as tiny containers.”

Professor Yamamoto

The group utilized X-beam crystallography and filtered electron microscopy to concentrate on the subsequent designs. The side walls of the vessels became outward with hexagonal evenness, leaving a void inside the features. The size of the side walls was viewed as almost consistent, with a thickness of only 500 nanometers. The scientists additionally showed areas of strength for how connections give the vessel mechanical strength. Numerous gem vessels can be manufactured all the while, and different shapes can be delivered. For instance, overabundance edge or body development brings about “blossom” or “gem” structures, individually.

“Empty gems with intricate morphologies and advanced glasslike edges and features can be exceptionally valuable as small compartments,” says Professor Yamamoto. As a proof-of-idea, the group liquefied a minuscule example inside a precious stone vessel and tracked down that the subsequent fluid remained inside. Based on this, we could see another sort of miniature experimental lab gear, in which responses can be performed with very modest quantities of synthetics.

More information: Osamu Oki et al, Synchronous assembly of chiral skeletal single-crystalline microvessels, Science (2022). DOI: 10.1126/science.abm9596

Journal information: Science