Created by the College of Wisconsin-Madison Designs, a lightweight, ultra-shock-retaining foam could immensely further develop caps intended to shield individuals from solid blows.

The new material shows multiple times higher explicit energy retention than the foam as of now utilized in U.S. military battle cap liners, as well as having a lot more prominent strength and firmness, which could permit it to give further developed impact security.

Actual powers from an effect can cause injury to the mind, causing a blackout. Yet, cap materials that are better at retaining and dispersing this motor energy before it arrives at the mind could help relieve, or even forestall, blackouts and other awful cerebrum wounds.

The scientists’ business accomplice, cap maker Group Wendy, is trying different things with the new material in a cap liner model to explore its exhibition in genuine situations.

“This new material has huge promise for energy absorption and consequently impact reduction, which should significantly reduce the likelihood of brain injury,”

Ramathasan Thevamaran, a UW–Madison professor of engineering physics

“This new material holds huge potential for energy retention and hence influence relief, which thus ought to essentially bring down the probability of mind injury,” says Ramathasan Thevamaran, a UW-Madison teacher of designing physical science who drove the exploration.

The group itemized its development in a review distributed as of late in the journal Outrageous Mechanics Letters.

Komal Chawla, a postdoctoral exploration partner at the University of Wisconsin-Madison, studies the architected in an upward direction adjusted carbon nanotube froth in the lab.

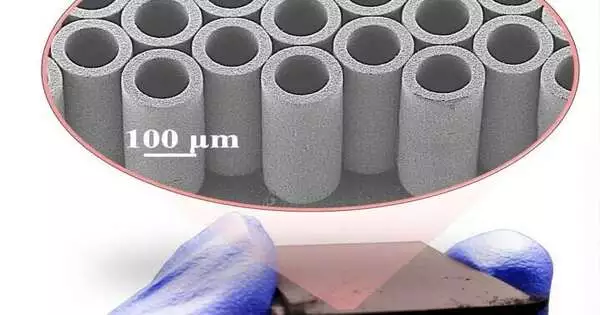

The new material is an architected carbon nanotube foam that adjusts upward. To make it, the analysts began with carbon nanotubes—carbon chambers only one iota thick in each layer—as the essential structure blocks.

As of now, carbon nanotubes have uncommon mechanical properties, and to further improve their exhibition, the scientists planned a material with novel primary elements across various length scales. The material’s clever design comprises various micrometer-scale chamber structures, each made of numerous carbon nanotubes.

Finding the new froth’s definitive ideal plan boundaries, like the thickness of the chambers, their inward width, and the hole between nearby chambers, was very difficult. The analysts efficiently led tests where they changed every boundary and concentrated on every one of the potential mixes.

“So we took a couple thicknesses and afterward tried that with each width size and each conceivable hole, etc.,” Thevamaran says. “Out and out, we took a gander at 60 unique mixes and led three tests on each example, so 180 trials went into this review.”

They revealed a reasonable champ. Chambers with a thickness of 10 micrometers or less, organized near one another, created a froth with the best shock-retaining properties.

“I anticipated that the general properties should work because of our intuitive design, yet I was amazed by how decisively the properties were upgraded when the chambers were 10 micrometers thick,” Thevamaran says. “It was caused by an unusual size impact in the process-structure-property relations. The impact was extremely articulated, and it ended up being very favorable for the properties we were focusing on.”

Moreover, the new material can remain highly shock-retaining at both high and low temperatures due to its carbon nanotube building blocks, making it helpful for applications in many outrageous conditions.

The analysts, including Komal Chawla, a UW-Madison postdoctoral exploration partner, and graduate understudies Abhishek Gupta and Abhijeet S. Bhardwaj, are licensing their advancement through the Wisconsin Graduated Class Exploration Establishment. The college business cooperation was essential for the UW-Madison-driven Puma program, an interdisciplinary exploration drive that is creating answers for empowering better location and avoiding awful mental wounds.

More information: Komal Chawla et al, Superior mechanical properties by exploiting size-effects and multiscale interactions in hierarchically architected foams, Extreme Mechanics Letters (2022). DOI: 10.1016/j.eml.2022.101899