A biosensor is a measuring system that consists of a probe containing a sensitive biological detecting material or a biological receptor, a physics-chemistry detector element, and a transducer. The sensitive biological element, which may include tissue, microorganisms, organelles, cell receptors, enzymes, antibodies, nucleic acids, and so on, is a biologically derived material or biomimetic component that interacts with, binds to, or recognizes the analyte under investigation. Biological engineering can also be used to create biologically sensitive elements.

Chemical engineers have developed a process that converts clothing fabric into biosensors that measure the electrical activity of muscles while they are worn. This could be a far superior method of measuring muscle activity for physical rehabilitation or other medical applications. You are what you wear, they say. That is made even more true by new biosensor technology developed at the University of Utah’s College of Engineering.

Huanan Zhang, an assistant professor of chemical engineering, has developed a method for converting clothing fabric into biosensors that measure a muscle’s electrical activity as it is worn. His novel technology was recently described in a paper published in the scientific journal APL Materials. Taehwan Lim, a chemical engineering graduate student at the University of Utah, and Sohee Lee from the Department of Clothing and Textiles at Gyeongsang National University in South Korea co-authored the paper, “Gold and silver nanocomposite-based biostable and biocompatible electronic textile for wearable electromyographic biosensors.” A copy of the paper can be found here.

With this new method, clinicians will be able to collect a muscle’s long-term electrical signals with greater precision. We can also gain a better understanding of a patient’s progress and, as a result, therapeutic outcomes over time.

Huanan Zhang

Zhang and his colleagues developed a method for transforming ordinary cotton/polyester blend fabrics into sensors that measure electrical impulses generated by muscle movement. This could be a far superior method of measuring muscle activity for physical rehabilitation or other medical applications. Normally, current bioelectrical sensor technology, in which sensors with wires are taped to the skin, can be ineffective, uncomfortable, expensive, and costly to manufacture.

“With this new method, clinicians will be able to collect a muscle’s long-term electrical signals with greater precision,” Zhang says. “We can also gain a better understanding of a patient’s progress and, as a result, therapeutic outcomes over time.”

When human muscle contracts, electrical signals in the form of ions are released (as opposed to electrons from an electrically powered device). Zhang’s method entails depositing a microscopic layer of silver over a piece of fabric to make it conductive and thus capable of receiving electrical signals from the muscle.

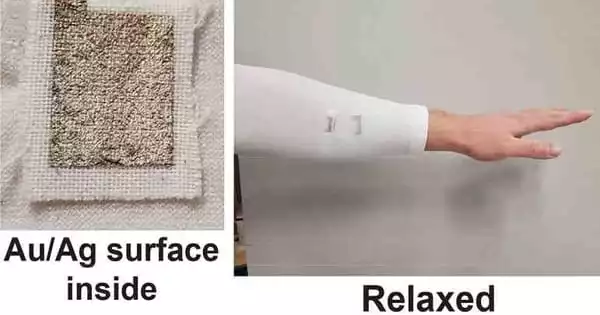

However, having only a layer of silver is a problem because the metal can be toxic when in prolonged contact with the skin. As a result, the researchers add a second microscopic layer of gold that is non-toxic to the touch. According to Zhang, the gold not only protects the skin from the silver, but also improves the electrical signal. “The silver layer provides a baseline conductivity, but the gold on top improves the signal and biocompatibility while also lowering the cost of manufacturing pure gold devices,” he says.

The silver layer is applied to the fabric in a manner similar to screen printing a graphic onto a T-shirt, and it is only applied to the areas of the clothing that come into contact with the muscle being measured. The gold layer is then deposited electrochemically. Sensor patches are then connected to wires and portable electromyography (EMG) device, which measures muscle contractions.

Zhang emphasizes that the process is also resistant to repeated cycles in a washing machine. His team subjected a piece of clothing treated with the process to 15 washes, which had no effect on the sensors’ efficacy.

Zhang and his colleagues are currently testing the method on a compression sleeve for the forearm. While this technology is most likely to be used on compression sleeves or socks because it requires the clothing to be in constant contact with the skin, Zhang believes it could also be used on other skin-tight clothing such as bicycle pants or athletic tights.

This sensor-enabled clothing is yet another example of the popular trend of wearable technologies that continuously monitor your health throughout the day, such as the Apple Watch. And, if EGM monitors become small enough, Zhang envisions his clothing interacting with a digital watch to provide real-time readings.