Basic minerals, including uncommon earth components, are utilized to drive gadgets like cell phones and PCs and are vital for our country’s economy and public safety. Penn State’s Middle for Basic Minerals has fostered another purging cycle that concentrates blended uncommon earth oxides from corrosive mine waste and related slops at purities of 88.5%.

Basic minerals (CMs), including the 17 uncommon earth components (REEs), are utilized in numerous normal family items like cell phones and PCs and in numerous business items like electric vehicles, batteries, and sun-powered chargers. They are called “basic” because they have a high monetary significance, a high stock gamble, and their absence would have a significant impact on the US’s financial and public safety.

Corrosive mine waste (AMD) and related solids and hastens coming about because of AMD treatment have been viewed as suitable wellsprings of various CMs, including REEs, aluminum, cobalt, and manganese.

“We’ve been working hard to create ways for recovering CMs and REEs from these waste streams, and we’ve reached a significant milestone of 88.5% grade REEs. The current DOE target for achieving mixed rare earth oxides is 75%, which we have exceeded.”

Sarma Pisupati, professor of energy and mineral engineering and director of the Center for Critical Minerals at Penn State.

The U.S. Department of Energy (DOE) has financed endeavors to show both the specialized possibility and monetary suitability of removing, isolating, and recuperating REEs and CMs from U.S. endless coal result sources, fully intent on accomplishing blended uncommon earth oxides from coal-based assets with least purities of 75%.

“We have been attempting to foster systems to recuperate CMs and REEs from these waste streams and have accomplished an achievement of 88.5% grade REEs,” said Sarma Pisupati, teacher of energy and mineral design and head of the Middle for Basic Minerals at Penn State. “The ongoing objective set by the DOE for accomplishing blended uncommon earth oxides is 75%, and we have outperformed that objective.”

Corrosive mine waste and related slop material addressing the Lower Kittanning coal bed were gotten from three treatment locales worked by the Pennsylvania Branch of Natural Security and were described and assessed for the recovery of various basic minerals.

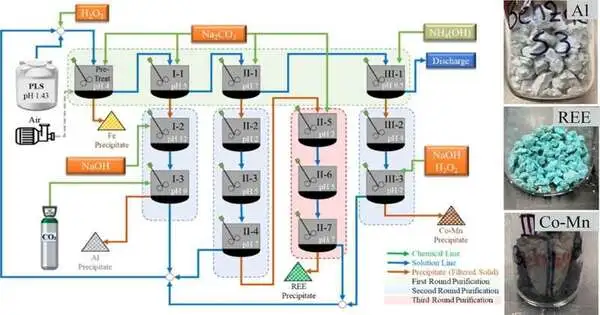

A clever purging cycle, in view of a formerly evolved three-stage AMD treatment process, was intended to recover high-grade aluminum, REE, cobalt, and manganese items from the muck materials through fluid handling with various cleaner steps and exact control of the cycle boundaries, as per the scientists.

“The straightforward extraction of REEs and CMs from AMD eliminates the requirement for ooze disintegration and related expenses of reagents and handling, resulting in more feasible garbage removal rehearsals with minimal expense,” said Mohammad Rezaee, assistant professor of mining design at Penn State and co-creator on the review.”We have shown that we can turn these waste streams, which have been natural worries for quite a long time, into important assets, so this is a shared benefit for the climate, the ward, and the country.”

AMD is normally treated by adding lime or different synthetics to raise the pH to 7.

“Normally, AMD is killed through the expansion of different basic synthetics,” said Rezaee, who likewise holds the Centennial Vocation Improvement Residency in Mining Designing. “As the pH of the AMD increments during the treatment cycle, metals hasten as metal hydroxides or different edifices.”

The pH in the new framework has not yet been raised to 7, but it will be done gradually.

“Rather than adding sodium hydroxide, calcium hydroxide, or lime at the same time to raise the pH, we are bringing it up in stages,” said Pisupati. “The upside of this strategy is that it permits specific minerals to hasten out at various pH levels.” Assuming we include our base at the same time and bring the pH to 7, everything will hasten simultaneously. Then we would have to return and separate them.”

The analysts raised the pH to the level required for iron to hasten and then to the pH required for aluminum to encourage. After iron and aluminum are taken out, REEs are recovered through carbonate precipitation, as per the analysts.

“Our test was that we were unable to get 100 percent of the iron and aluminum eliminated; there was a tad of buildup in the REE focus,” said Pisupati. “Regardless of whether you have just 1% of aluminum content in the blend, it rules, and the nature of your uncommon earths won’t be as unadulterated.” This was tended to in the new purging cycle.

Hastens that were removed are returned to the purging system, but the cycle continues to eliminate iron, aluminum, and other deposits.

“In the purging system, we go through the cycle once more, returning to a pH of 3 or 3.5 and starting from the very beginning,” said Pisupati. “We are disposing of different deposits gradually, perhaps twice or multiple times through the cycle, to build the REE virtue.” “In our past exploration, we were at around 17% to 18% grade, so this is a huge achievement.”

Recuperations of over or close to 100% for the objective components were accomplished with the plan of reusing the load. In the first three-stage precipitation process, the cobalt and manganese hastens had a grouping of 0.85% and 23%, respectively. Because of the purging system, their focuses were expanded to 1.3% and 43%, respectively.

The examination was distributed in Minerals Designing.

More information: Behzad Vaziri Hassas et al, Selective recovery of high-grade rare earth, Al, and Co-Mn from acid mine drainage treatment sludge material, Minerals Engineering (2022). DOI: 10.1016/j.mineng.2022.107813