Propelled by the need to dispose of costly uncommon earth magnets in utility-scale direct-drive wind turbines, Sandia Public Labs scientists fostered a new sort of rotational electrical contact. Sandia is currently preparing to join forces with the sustainable power industry to foster the up and coming age of direct-drive wind turbines.

Sandia’s Twistact innovation adopts a clever strategy to communicate electrical flow between a fixed and pivoting outline, or between two turning congregations having various velocities or rotational headings, ideal for application in wind turbines.

“Twistact started by asking ourselves a few truly testing inquiries,” said Jeff Koplow, Sandia research researcher and specialist. “We realized it very well may be down changing if we figured out how to get around the restricted assistance lifetime of traditional rotating electrical contacts.”

“I got the impression that maybe a few out of every odd possible rotating electrical contact design had been considered at this point,” Koplow said.”We invested a ton of energy considering that there was another conceivable way.”

“Twistact began when we asked ourselves some difficult questions. We realized that overcoming the limited service lifetime of conventional rotary electrical connectors may be game-changing.”

Jeff Koplow, Sandia research scientist and engineer.

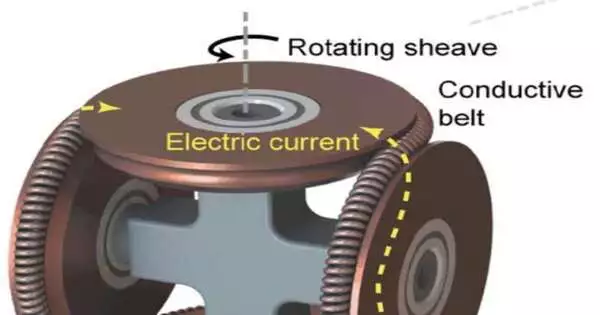

The subsequent development, Twistact, utilizes an unadulterated rolling-contact gadget to communicate electrical flow along a super low-obstruction path. The innovation is beneficial in terms of cost reduction, increased maintainability, and decreased upkeep.

Taking out dependence on interesting earth metals.

The vast majority of the ongoing utility-scale wind turbines are reliant upon intriguing earth magnets, Koplow said. These materials come at a high initial expense and are defenseless against inventory network vulnerabilities.

In 2011, for instance, there was an uncommon earth materials production network emergency that caused the cost of neodymium and dysprosium, the two interesting earth components broadly utilized for such magnets, to soar. This could hinder the development of the business. The Sandia group started creating Twistact at the time as a support to shield the developing breeze industry from future disturbances.

When you show up that uncommon earth metals have forever been hard to find, that their digging is famous for its antagonistic ecological effect, and that contending applications, for example, electric vehicles, are likewise putting expectation on intriguing earth metals, the incentive of Twistact turns out to be clear,” Koplow said.

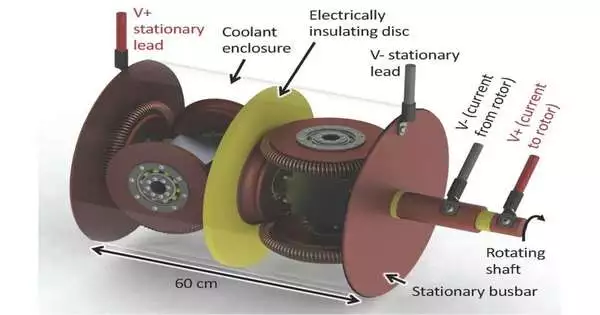

Realistic representation of the fundamental guideline of the Twistact activity. Sandia Public Research facilities is presently prepared to cooperate with the sustainable power industry to move the innovation to foster the up and coming age of direct-drive wind turbines. Credit: Sandia Public Research facilities

No support or substitution costs

Furthermore, Sandia’s Twistact innovation tends to two actual corruption processes normal to high-support brush or slip ring congregations — sliding contact and electrical arcing. These restricting variables lessen the presentation of conventional rotational electrical contacts and lead to short working lifetimes and high support or substitution costs.

Twistact, then again, has been demonstrated through research facility testing to be equipped for working over the full 30-year administration season of a multimegawatt turbine without upkeep or substitution.

Other likely applications for the innovation incorporate simultaneous engines and generators, jolted rail lines and radar towers. Twistact could also be used to replace brush or slip rings in existing applications.

Provided by Sandia National Laboratories