Scientists have made a significant stride towards 3D laser-printed materials that could be utilized in surgeries to embed or fix clinical gadgets.

A group of researchers, led by specialists at Lancaster College, has fostered a technique to 3D-print adaptable hardware utilizing the leading polymer polypyrrole, and they have shown that it is feasible to directly print these electrical designs on or in living life forms (roundworms).

Their discoveries are accounted for in the paper Making 3D articles with coordinated hardware through multiphoton manufacture in vitro and in vivo, which is distributed in Cutting Edge Material Advances.

“We inserted 3D printed electrodes on a slice of mouse brain tissue that was kept alive in vitro. Using this method, we were able to elicit neural responses identical to those seen in vivo. Implants that can be easily modified for a wide range of tissues have both therapeutic and research applications.”

Dr. Damian Cummings, Lecturer in Neuroscience at University College London,

In spite of the fact that at the proof-of-concept stage, specialists trust that this kind of cycle, when completely created, can possibly print patient-explicit inserts for different applications, including continuous wellbeing observation and clinical mediations, for example, treating epilepsy or torment.

Dr. John Solid, Senior Teacher in Materials Science at Lancaster College and one of the lead creators of the review, said, “This approach possibly changes the assembly of mind-boggling 3D hardware for specialized and clinical applications — including structures for correspondence, presentations, and sensors, for instance. Such methodologies could alter the manner in which we embed yet additionally fix clinical gadgets. For instance, one day, innovations like this could be utilized to fix broken embedded gadgets through an interaction like a laser dental or eye medical procedure. When completely experienced, such innovation could change an at present significant activity into a lot easier, quicker, more secure, and less expensive system.”

In a two-stage study, the scientists utilized a Nanoscribe (a high-goal laser 3D printer) to 3D-print an electrical circuit directly inside a silicone lattice (using an added substance process). They showed the way that this hardware can animate mouse neurons in vitro (like how brain terminals are utilized for profound cerebrum excitement in vivo).

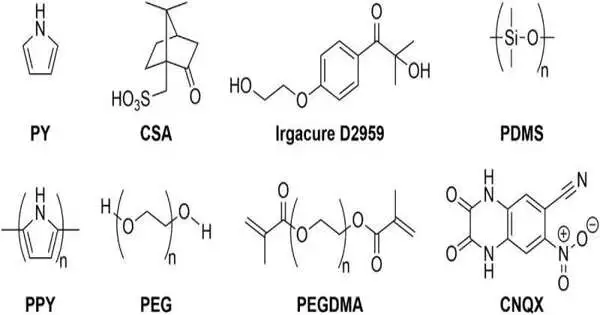

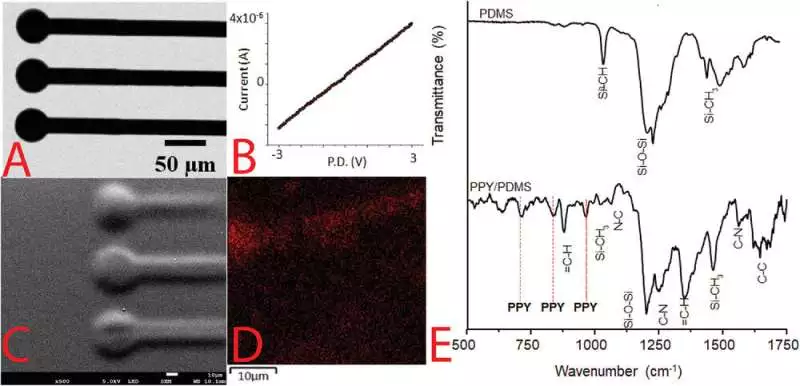

A) Optical magnifying instrument picture of a model PPY/PDMS structure (scale bar addresses 50 m). B) FTIR spectra of PDMS and PPY/PDMS structures C) SEM picture of a model PPY/PDMS structure (scale bar addresses 10 m). D) EDX picture of a model PPY/PDMS structure, where the power of K outflow of C (red) is planned in comparison with the foundation PDMS (dark); the scale bar addresses 10 m. E) FTIR spectra of PDMS and PPY/PDMS Credit: High-Level Materials Innovations (2023) DOI: 10.1002/admt.202201274

Dr. Damian Cummings, a teacher in neuroscience at College School London and a co-creator of the review who led the cerebrum feeling work, said, “We took 3D-printed terminals and put them on a cut of mouse mind tissue that we kept alive in vitro. Utilizing this methodology, we could bring out neuronal reactions that were like those seen in vivo. Promptly modified inserts for a large number of tissues offer both restorative potential and can be used in many exploration fields.”

In the second phase of the review, the scientists 3D-printed leading designs straightforwardly in nematode worms, demonstrating that the full cycle (ink definitions, laser openness, and printing) is viable with living creatures.

Dr. Alexandre Benedetto, Senior Teacher in Biomedicine at Lancaster College, and another lead creator of the review said, “We basically inked conductive patches on small worms utilizing brilliant ink and lasers rather than needles. It showed us that such innovation can accomplish the goal and provide the security and comfort levels expected for clinical applications. In spite of the fact that improvements in infrared laser innovation, brilliant ink planning, and conveyance will be basic to making an interpretation of such ways to deal with the facility, it prepares for exceptionally thrilling biomedical advancements.”

The specialists accept these outcomes as a significant step featuring the potential for added substance fabrication ways to deal with producing cutting-edge material advances — specifically, coordinated hardware for specialized and customized clinical applications.

The subsequent stages in the improvement in research are as of now in progress: investigating the materials in which it is feasible to print, the sorts of designs it is feasible to print, and creating models to feature to potential end clients who might be keen on the co-advancement of the innovation. The analysts accept that innovation is around 10 to a long time from being completely evolved.

More information: Sara J. Baldock et al, Creating 3D Objects with Integrated Electronics via Multiphoton Fabrication In Vitro and In Vivo, Advanced Materials Technologies (2023). DOI: 10.1002/admt.202201274