A new Cornell University study examines the long-term energy and sustainability prospects of U.S. production and highlights policy approaches for building a more resilient battery supply chain in light of the federal government’s encouragement of domestic production of electric vehicle batteries.

EV batteries are generally fabricated abroad, and numerous strategy creators need to move more creation to the U.S.—a training known as reshoring — to diminish reliance on imported products and flighty worldwide stock chains. But reshoring will also affect the country’s climate goals and the transition to renewable energy.

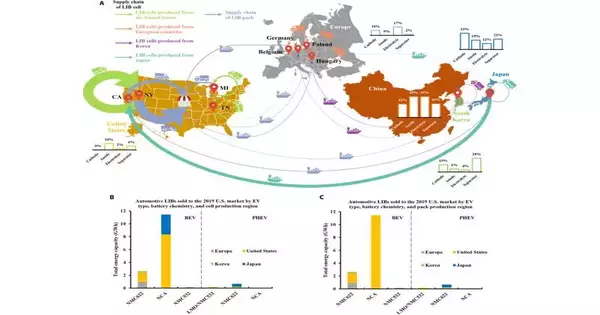

One of the most comprehensive energy and environmental analyses of reshoring lithium-ion EV batteries, taking into account the entire life cycle, including the acquisition of raw materials, component production, manufacturing, distribution, and transportation, was published on June 14 in Science Advances.

“The type of advanced modeling and systems analysis provided by this study is critical for considering the environmental tradeoffs in how lithium-ion batteries are built, as well as securing a resilient midstream and downstream value chain for the United States in the face of uncertain markets and evolving battery technologies.”

Co-author Apoorv Lal, a graduate student in You’s Process-Energy-Environmental Systems Engineering Lab,

Reshoring has the potential to reduce the overall carbon footprint of U.S. EV batteries as well as the energy required to manufacture them, according to the study. However, benefits can vary greatly depending on factors like technological advancements, supply chain restructuring, and the adoption of electric vehicles.

According to Fengqi You, co-lead author of the study and senior faculty fellow at the Cornell Atkinson Center for Sustainability and the Roxanne E. and Michael Zak Professor of Energy Systems Engineering, “for example, utilizing recycled aluminum and nickel can reduce the carbon footprint for the pre-pandemic U.S. electric vehicle fleet by up to 26%.” Data science and sustainability analytics will play a crucial role in shaping the future of energy, climate, manufacturing, and environmental policy, as shown by this study.

An ally-shoring strategy, in which production capacities for refined metals and battery components are relocated to countries in the European Union, South Korea, and Japan, was also examined for its energy and sustainability potential.

The study’s findings include:

- The carbon footprint of the future U.S. EV battery supply chain could be reduced by up to 27% by increasing the proportions of onshoring and allied production.

- The environmental sustainability of EV batteries would be enhanced by reducing reliance on hard coal and lignite-fired electricity and increasing the proportion of renewable energy in the power grid.

- Climate change mitigation benefits can be improved by 54% by strategically integrating battery technology advancement and supply chain restructuring.

- Despite the fact that reshoring could reduce ecotoxicity and the production of fine particulate matter from secondary nickel supply by more than 30%, there is a decrease in environmental performance in terms of ozone formation, ozone depletion, and ionizing radiation as a result of the increasing distance that materials must be transported overseas.

According to study co-author Apoorv Lal, a graduate student in You’s Process-Energy-Environmental Systems Engineering Lab, “the type of advanced modeling and systems analysis offered by this study is essential for considering the environmental tradeoffs in how lithium-ion batteries are built” and “for securing a resilient midstream and downstream value chain for the U.S. amidst uncertain markets and evolving battery technologies.”

More information: Apoorv Lal et al, Will reshoring manufacturing of advanced electric vehicle battery support renewable energy transition and climate targets?, Science Advances (2023). DOI: 10.1126/sciadv.adg6740