A creep cycle can occur when a metal is concentrated far beneath its yield strength at elevated temperatures.Creep, the time-subordinate twisting of materials, is liable for an extraordinary number of part disappointments at high temperatures. Researchers realize that wiping out grain limits in materials is a helpful approach to opposing high-temperature creep in metals. Nonetheless, a group of scientists has fostered an alternate system for repressing killjoy by utilizing stable grain limit organizations.

Their discoveries are distributed in the journal Science on November 10, 2022.

The group’s methodology for a property improvement differs on a very basic level from that of conventional procedures. “When primary unwinding of grain limits is set off through their cooperation with fractional disengagements under a basic grain size, the ways of grain limit organizations may be generally cautioned,” said Li Xiuyan, a teacher at the Establishment of Metal Exploration, Chinese Foundation of Sciences.Using their new technique, the team created an extraordinary wet blanket obstruction that outperformed that of standard superalloys.

Creep is an expensive issue. An incredible number of failures of materials and parts at high temperatures are credited to crawling or to its blend with other corruption processes. These disappointments cost billions of dollars a year for the maintenance and substitution of parts in cutting-edge gadgets. The interest in higher eco-friendliness and more solid turbines, atomic reactors, and gadgets in substance ventures keeps on developing. With this growing interest, there is a growing demand for improved high-temperature creep resistance in cutting-edge compounds.

“The behaviors of grain boundary networks may be fundamentally changed when structural relaxation of grain borders is initiated by their contact with partial dislocations below a certain grain size,”

Li Xiuyan, a professor at the Institute of Metal Research

“Customary advancement of compounds for high-temperature applications is fundamentally dependent on the talented expansion of different alloying components for fortifying the grid or points of interaction, or for shaping up buildings,” said Li. “Such a system faces the challenge of limited property improvement with increasing alloying and increasing cost.”

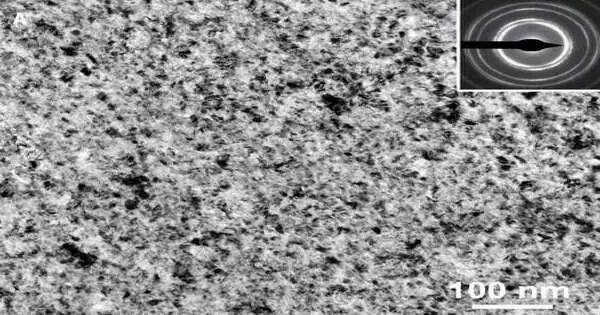

Grain limits, also known as deserts in precious stone construction, are the points at which two gems with opposing directions meet.Albeit the customary way of thinking focuses on the disposal of grain limits to counter the issue of creep, the exploration group proposed acquainting bountiful grain limits with stable grain limit networks in metal to hinder creep by smothering nuclear dissemination and solidifying at high temperatures all the while. The plan to adopt this strategy was prompted by late examinations on grain limit unwinding in metals.

The group discovered that grain limits can be used for reinforcing compounds at elevated temperatures, contrary to popular belief that they generally debilitate the amalgams at high temperatures.It is known that grain limits in metals and combinations are typically thought to be “powerless parts,” as they might relocate or slide after stacking at raised temperatures.

“We discovered that grain limits in the nanograined single-stage composite can be really balanced out through primary unwinding, and the compound’s wet blanket exhibition is essentially improved at higher temperatures,” Li said.Grain limit unwinding, in contrast to the conventional alloying approach, offers a novel and reasonable technique for propelling properties and execution of compounds for high-temperature applications.

Looking forward to future exploration, the group sees space for dependability improvement by fitting grain limit networks in metals and composites. “As a result, the next stage of this research will be to extend this guideline to other combination families for high-temperature applications, such as nickel-based composites and prepares,” Li explained.

The group intends to perform handling advancement to further advance the strength of grain limit organizations and to prepare massive-size tests for estimations of additional properties and performance at high temperatures. “At long last, we want to recognize the modern applications of superior operational efficiency combinations with stable grain limit organizations,” Li said.

More information: Li Xiuyan et al, Inhibiting creep in nanograined alloys with stable grain boundary networks, Science (2022). DOI: 10.1126/science.abq77

Journal information: Science