What does it take to create green hydrogen all the more productively and economically? Clearly, little ruthenium particles and a sunlight-based controlled framework for water electrolysis. This is the arrangement proposed by a joint group including the Istituto Italiano di Tecnologia (Italian Organization of Innovation, IIT) of Genoa and BeDimensional S.p.A. (an IIT spin-off).

A new family of electrocatalysts is the foundation of the technology, which was developed as part of the activities of the joint lab and was recently published in Nature Communications and the Journal of the American Chemical Society. It has the potential to lower the costs of industrial green hydrogen production.

Hydrogen is viewed as a supportable energy vector, an option in contrast to petroleum products. However, in terms of its impact on the environment, not all hydrogen is created equal. For sure, the fundamental way hydrogen is created these days is through methane steam changing, a non-renewable energy source-based process that discharges carbon dioxide (CO2) as a result. When CO2 is captured and stored in the earth’s crust, it is categorized as “gray” or “blue,” depending on the color of the hydrogen it produces.

To essentially lessen emanations to zero by 2050, these cycles should be supplanted with additional naturally manageable ones that convey “green” (i.e., net-zero outflows) hydrogen. The expense of “green” hydrogen fundamentally relies upon the energy productivity of the arrangement (the electrolyzer) that parts water atoms into hydrogen and oxygen.

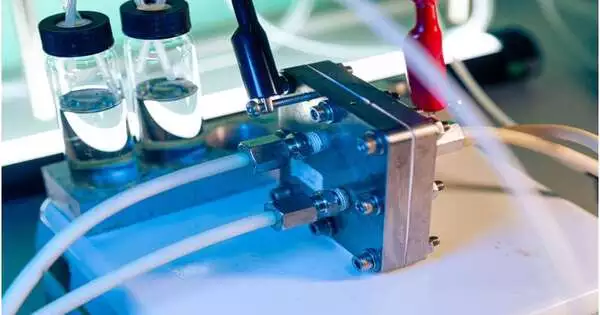

In order to convert the electrical energy (the energy bias utilized to split water molecules) into the chemical energy that is stored in the produced hydrogen molecules, the researchers from the joint team that made this discovery have developed a novel approach that guarantees greater efficiency than the methods that are currently in use. The group has fostered the idea of an impetus and has utilized environmentally friendly power sources, for example, the electrical energy delivered by a sunlight-based charger.

“We have demonstrated in our study that it is possible to maximize the efficiency of a robust, well-developed technology despite a slightly higher initial investment than would be required for a standard electrolyzer.” According to Yong Zuo and Michele Ferri of the Nanochemistry Group at IIT in Genoa, “This is because we are using a precious metal such as ruthenium.”

The scientists utilized nanoparticles of ruthenium, a respectable metal that is like platinum in its substance conduct but is far less expensive. “We have conducted electrochemical analyses and tests under industrially significant conditions that have enabled us to assess the catalytic activity of our materials. Ruthenium nanoparticles serve as the active phase of the electrolyzer’s cathode.” Moreover, hypothetical recreations permitted us to comprehend the synergist conduct of ruthenium nanoparticles at the sub-atomic level; in other words, the way water splits on their surfaces,” the researchers from BeDimensional, Sebastiano Bellani and Marilena Zappia, explained.

“We have carried out a techno-economic analysis that demonstrated the competitiveness of this technology when compared to state-of-the-art electrolyzers,” the authors write. “Combining the data from our experiments with additional process parameters.”

Ruthenium is a valuable metal that is gotten in small amounts as a side effect of platinum extraction (30 tons each year, when contrasted with the yearly creation of 200 tons of platinum), yet at a lower cost (18.5 dollars per gram rather than 30 bucks for platinum). The new innovation includes the utilization of only 40 mg of ruthenium for every kilowatt, as a conspicuous difference from the broad utilization of platinum (as much as 1 gram for each kilowatt) and iridium (somewhere in the range of 1 and 2.5 grams for each kilowatt, with iridium costing around 150 bucks for each gram) that portray proton-trade layer electrolyzers.

Alkaline electrolyzers, a technology that has been in use for decades due to its robustness and durability, have seen an increase in efficiency thanks to the use of ruthenium by researchers at IIT and BeDimensional.

For instance, this innovation was ready for the Apollo 11 case that brought humankind to the moon in 1969. The new group of ruthenium-based cathodes for soluble electrolyzers that has been created is extremely proficient and has a long working life, being in this way fit for diminishing the creation expenses of green hydrogen.

The researchers came to the following conclusion: “In the future, we plan to apply this and other technologies, such as nanostructured catalysts based on sustainable two-dimensional materials, in up-scaled electrolyzers powered by electrical energy from renewable sources, including electricity generated by photovoltaic panels.”

More information: Yong Zuo et al, Ru–Cu Nanoheterostructures for Efficient Hydrogen Evolution Reaction in Alkaline Water Electrolyzers, Journal of the American Chemical Society (2023). DOI: 10.1021/jacs.3c06726