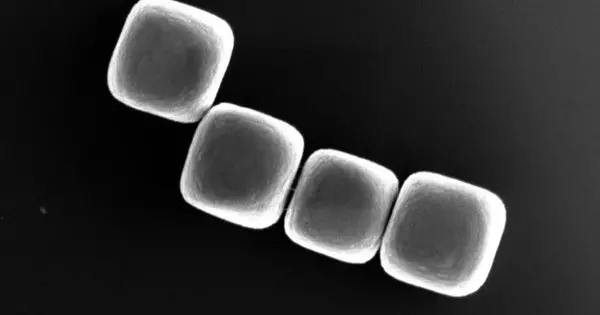

Specialist Laura Rossi and her team at TU Delft have found a better approach to fabricating manufactured materials out of minuscule glass particles called “colloids.” Together with their associates from Queen’s University and the University of Amsterdam, they demonstrated the way that they can just utilize the state of these colloids to make intriguing structure blocks for new materials, paying little heed to the different properties of the colloidal particles. “This is striking since it opens up a totally better approach to contemplating materials planning,” Rossi says. Their work is distributed in Science Advances this Friday.

Colloids are small particles, a couple of nanometers to a couple of microns in size. They comprise an assortment of particles and can have various properties depending upon the material they are made of. “In specific situations, colloids can act like iotas and atoms, yet their cooperation is a major area of strength for less,” makes sense. “That makes them promising building blocks for new materials, for instance for intelligent materials that can adjust their properties to their current circumstance.”

“Colloids can behave like atoms and molecules in some circumstances, but their interactions are weaker. This makes them attractive building pieces for novel materials, such as interactive materials that can alter their properties to their surroundings,”

Researcher Laura Rossi

An improved approach to material planning

If left alone, the block-formed colloids in this review, which are made of glass, will congregate into simple shapes like contorted cubic and hexagonal cross-sections. In any case, rather than going promptly from the structure block to the last construction, the scientists took little gatherings of colloids and consolidated them into greater structure blocks. When they collected these bunches of colloids, they wound up with an alternate final design with unexpected material properties in comparison to their own gathered structure. “According to a science perspective, we generally center around how we can deliver a particular sort of colloid,” Rossi says. “In this review, we’ve moved our concentration to: how might we utilize the colloids that are as of now accessible to make fascinating structure blocks?”

A step forward

According to Rossi and her partner Greg van Anders, one of the ultimate goals of their research area is to plan complex colloidal designs on demand.”What we found here is vital, on the grounds that for potential applications, we want to have a methodology that can be increased, which is something that will be difficult to accomplish with most presently accessible methodologies.” “The fundamental capacity to pre-gather indistinguishable pieces from various structural hinders and have them make a similar construction, or to take a similar structure block and pre-collect various pieces that make various designs, are actually the essential ‘chess moves’ for designing complex designs,” adds van Anders.

Despite the fact that Rossi concentrates on the central viewpoints instead of the use of materials, she can imagine inevitable applications for this particular work: “We found that the thickness of the construction that we arranged was a lot slower than the thickness of the design you would get by utilizing the beginning structure blocks.” So you can contemplate seriously lightweight materials for transportation. “

Collaborating

After Rossi’s group constructed bunches of colloids in the lab, they depended on the group of Greg van Anders from Queen’s University to fabricate the last design out of pre-collected bunches with a virtual experience. “With these sorts of tasks, it’s perfect to have the option to collaborate with other people who can run reenactments, not exclusively to comprehend what’s going on top to bottom, but in addition to test how enormous the opportunity of an effective lab examination will be,” Rossi makes sense of. “Also, for this situation, we obtained exceptionally persuasive results,” meaning that we understood the plan interaction well and that the subsequent material could be helpful.

The following stage will be to really fabricate the last construction produced using the gatherings of colloids in the lab. “Subsequent to seeing these outcomes, I’m certain that it very well may be finished,” says Rossi. “Having an actual variant of this material and grasping it would be perfect.”