Another counterfeit chemical has shown it can bite through lignin, the extreme polymer that assists woody plants with holding their shape. Lignin likewise stores enormous potential for environmentally friendly power and materials.

Detailing in the diary Nature Communications, a group of specialists from Washington State University and the Department of Energy’s Pacific Northwest National Laboratory showed that their counterfeit catalyst prevailed with regards to processing lignin, which has determinedly opposed past endeavors to form it into a monetarily valuable energy source.

Lignin, which is the second most bountiful inexhaustible carbon source on Earth, generally goes to squander as a fuel source. At the point when wood is singed for cooking, lignin side-effects assist with granting that smoky flavor to food varieties. In any case, consuming deliveries generally that carbon to the climate as opposed to catching it for different purposes.

“This work definitely offers up new doors. This is a huge step forward in converting lignin into valuable products in an environmentally friendly manner.”

Chun-Long Chen

“Our profile impersonating catalyst showed guarantee in debasing genuine lignin, which is viewed as a forward leap,” said Xiao Zhang, a comparing creator on the paper and academic partner in WSU’s Gene and Linda Voiland School of Chemical Engineering and Bioengineering. Zhang likewise holds a joint arrangement at PNNL. “We think there is a chance to foster another class of impetuses and to address the constraints of natural and compound impetuses truly.”

Lignin is in all vascular plants, where it structures cell dividers and furnishes plants with unbending nature. Lignin permits trees to stand, gives vegetables their solidness and makes up around 20-35% of the heaviness of wood. Since lignin becomes yellows when presented to air, the wood items industry eliminates it as a component of the fine papermaking process. Once eliminated, delivering fuel and electricity is frequently wastefully singed.

Scientists have fallen flat for over hundred years to make significant items from lignin. That history of disappointment might be going to change.

One better than nature

“This is the main nature-mimetic protein which we know can proficiently process lignin to create intensifies that can be utilized as biofuels and for substance creation,” added Chun-Long Chen, a comparing creator, a Pacific Northwest National Laboratory scientist, and partner teacher in synthetic designing and science at the University of Washington.

In nature, growths and microscopic organisms can separate lignin with their proteins, which is the way a mushroom-shrouded log breaks down in the backwoods. Proteins offer a significantly more earth harmless interaction than synthetic debasement, which requires high intensity and consumes more energy than it produces.

However, regular compounds debase over the long haul, which makes them hard to use in a modern cycle. They’re costly, as well.

“It’s truly difficult to deliver these catalysts from microorganisms in a significant amount for down to earth use,” said Zhang. “Then once you seclude them, they’re extremely delicate and temperamental. Yet, these proteins offer an incredible chance to motivate models that duplicate their essential plan.”

While scientists have been not able to tackle normal catalysts to work for them, they have throughout the long term gained some significant knowledge about how they work. A new survey article by Zhang’s examination group frames the difficulties and hindrances toward the utilization of lignin debasing catalysts. “Understanding these hindrances gives new experiences toward planning biomimetic proteins,” Zhang added.

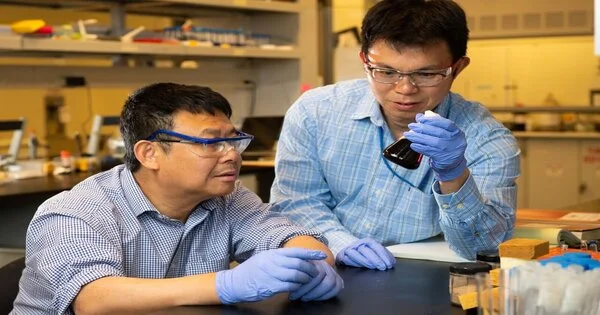

Specialists Xiao Zhang (L) and Chun-long Chen (R) inspect the results of lignin assimilation by their novel biomimetic peptoid impetus. Credit: Andrea Starr | Pacific Northwest National Laboratory

Peptoid framework is vital

In the ebb and flow study, the scientists supplanted the peptides that encompass the dynamic site of normal compounds with protein-like atoms called peptoids. These peptoids then self-collected into nanoscale glasslike cylinders and sheets. Peptoids were first evolved during the 1990s to copy the capacity of proteins. They have a few one of a kind elements, including high solidness, that permit researchers to address the lacks of the regular compounds. For this situation, they offer a high thickness of dynamic locales, which is difficult to get with a characteristic catalyst.

“We can exactly sort out these dynamic destinations and tune their neighborhood surroundings for synergist action,” said Chen, “and we have a lot higher thickness of dynamic locales, rather than one dynamic site.”

True to form, these fake chemicals are likewise significantly more steady and hearty than the normal variants, so they can work at temperatures up to 60 degrees Celsius, a temperature that would obliterate a characteristic compound.

“This work truly opens up new open doors,” said Chen. “This is a huge advance forward in having the option to change over lignin into important items utilizing an earth harmless methodology.”

In the event that the new bio-mimetic compound can be additionally improved to increment change yield, to create more specific items, it has potential for increase to modern scale. The innovation offers new courses to sustainable materials for avionics biofuel and biobased materials, among different applications.

The exploration coordinated effort was worked with through the WSU-PNNL Bioproducts Institute. Tengyue Jian, Wenchao Yang, Peng Mu, Xin Zhang of PNNL and Yicheng Zhou and Peipei Wang of WSU additionally added to the exploration.