Scientists have fostered a better approach to utilizing femtosecond laser heartbeats to create the high-accuracy ultrathin mirrors expected for elite X-beam telescopes. The method could assist with further developing the space-based X-beam telescopes used to catch high-energy vast occasions engaged in shaping new stars and supermassive dark openings.

Heng Zuo, who carried out the groundwork at MIT’s Kavli Foundation for Astronomy and Space Exploration and is presently at the College of New Mexico, said “Identifying vast X-beams is a vital piece of our investigation of the universe that reveals the high-energy occasions that pervade our universe yet are not detectable in different wavebands.” “The advances our gathering created will assist telescopes with getting sharp pictures of cosmic X-beams that can address many charming science questions.”

X-beam telescopes circle over the world’s air and contain a great many slim mirrors that should each have an exactly bended shape and be painstakingly lined up as for the wide range of various mirrors. In Optica, the scientists describe how they utilized femtosecond laser micromachining to twist these ultrathin mirrors into an exact shape and correct mistakes that can arise in the creation cycle.

“Detecting cosmic X-rays is an important part of our exploration of the cosmos because it reveals the high-energy events that pervade our universe but are not visible in other wavebands,”

Team leader Heng Zuo, who performed the research at MIT Kavli Institute for Astrophysics and Space Research

“It is hard to make super slim mirrors with a careful shape on the grounds that the creation cycle will in general seriously twist the slight material,” said Zuo. “Likewise, telescope mirrors are normally covered to increase reflectivity, and these coatings commonly twist the mirrors further. Our methods can address the two difficulties.

Accuracy bowing

Better approaches to creating super precise and elite-execution X-beam mirrors for telescopes are required as new mission ideas keep on stretching the boundaries of X-beam imaging. For instance, NASA’s Lynx X-beam Assessor idea will have the most remarkable X-beam optic at any point imagined and will require the production of countless super high-goal mirrors.

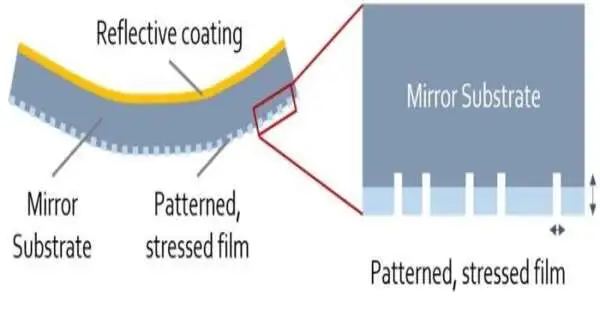

To address this issue, Zuo’s exploration group joined femtosecond laser micromachining with a formerly evolved method called pressure-based figure remedy. Stress-based Figure Remedy takes advantage of the bendability of slim mirrors by applying a deformable film to the mirror substrate to change its pressure states and prompt controlled bowing.

Zuo’s examination bunch joined femtosecond laser micromachining with a formerly evolved method called pressure-based figure remedy. The trial arrangement is shown. Heng Zuo, MIT Kavli Foundation for Astronomy and Space Exploration

The method includes specifically eliminating locales of a focused film developed onto the back surface of a level mirror. The analysts chose femtosecond lasers to achieve this on the grounds that the beats delivered by these lasers can make very exact openings, channels, and checks with minimal blow-back.

Likewise, the high redundancy pulses of these lasers permit quicker machining rates and throughput compared with customary techniques. This could assist with accelerating the creation of the huge quantities of super slim mirrors expected for cutting-edge X-beam telescopes.

Planning pressure

To apply the new methodology, the analysts initially needed to decide precisely how laser micromachining changes the mirror’s surface arch and stress states. Then they estimated the underlying mirror shape and made a guide of the pressure remedy important to making the ideal shape. They also developed a multi-pass correction plot that employs an input circle to repeatedly reduce errors until an acceptable mirror profile is obtained.

“Our trial results showed that designed expulsion of occasional openings prompts equibiaxial (bowl-molded) stress states, while fine-pitched arranged evacuation of intermittent boxes creates non-equibiaxial (potato-chip-formed) stress parts,” said Zuo.

“Joining these two elements with legitimate turn of the box direction, we can make an assortment of stress expressions that can, on a basic level, be utilized to address a blunder in the mirrors.”

In this work, the analysts showed the new method on level silicon wafers utilizing normal examples. To address genuine X-beam cosmology telescope mirrors, which are bent in two directions, the scientists are fostering a more perplexing optical arrangement for 3D development of the substrates.

More information: Heng Zuo et al, Femtosecond laser micromachining for stress-based figure correction of thin mirrors, Optica (2022). DOI: 10.1364/OPTICA.461870

Journal information: Optica