Forward assimilation (FO), a new film-based innovation, offers low energy utilization and low layer fouling potential; however, the lack of elite execution FO films limits FO’s widespread use.By and large, an ideal elite execution FO film ought to have high water porosity, low salt penetrability, low primary boundary (S esteem), great antifouling execution, and stable compound properties. Among them, nanofiber-upheld FO films have acquired fame.

Slim film composite (TFC) FO films made out of permeable substrates and super flimsy polyamide (Dad) specific layers show underlying model adaptability and prevalent porousness and selectivity. Yet, how might we beat the ‘compromise’ between water porousness and solute selectivity while limiting the general S-worth of FO films?

Moreover, Polyvinylidene fluoride (PVDF) is a semi-glasslike polymer with rehashing units, which is broadly used to plan film materials for water treatment due to their solid mechanical properties and stable compound properties. Yet, how might we create a deformity-free and strong Dad division layer on the electrospinning nanofibrous substrate (PVDF) with huge open surface pores through interfacial polymerization (IP)? Finally, how might we really ease the inner fixation polarization (ICP) peculiarity and film fouling in FO?

To address these inquiries, Prof. Miao Tian and Dr. Tao Mao from Northwestern Polytechnical College and their colleagues have worked together and detailed the plan of a double-layer-organized PVDF nanofiber-upheld TFC FO film. Their outcomes uncovered the way of behaving of foulants on the film surface and gave a hypothetical premise for the innovative work of high-water motion and hostile to contamination TFC FO layers in real wastewater treatment.

This study is distributed in the Boondocks of Natural Science and Designing.

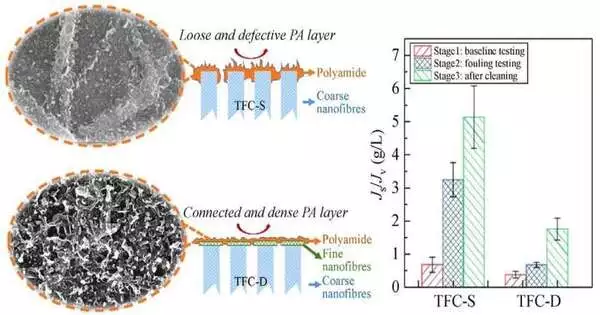

In the review, a layered PVDF nanofiber substrate with an ultrathin (1 m) fine fiber interlayer on top (normal fiber width of 40–60 nm) was effectively created by electrospinning. A Dad specific layer was blended utilizing IP on a previously mentioned nanofibrous substrate with different physicochemical properties. The FESEM and AFM techniques were utilized to concentrate on the impact of the electrospun nanofiber interlayer and drying time on the inborn division FO execution.

The division execution of the double layer nanofibrous FO films was analyzed utilizing model foulants (sodium alginate and ox-like serum egg whites) in both the feed arrangement (FS) and draw arrangement (DS). The double-layer nanofibrous substrate was better than the single-layer nanofibrous substrate and showed a transition of 30.2 LMH while involving 1.5 M NaCl against deionized water in the dynamic layer confronting draw arrangement mode.

In the fouling test, the water motion was really improved without forfeiting the water/solute selectivity under the condition that foulants existed in both the FS and DS. Also, the double-layered nanofibrous TFC FO film was more hearty during the fouling test and cleaning.

This study shows the significance of the interlayer in further developing the TFC FO film. The interlayer upgraded the selectivity of the Dad layer during long haul activity and cleaning. So, the review gives a hypothetical premise to the innovative work of high-water motion and hostile to contamination TFC FO films in genuine wastewater treatment.

More information: Tao Ma et al, Design of nanofibre interlayer supported forward osmosis composite membranes and its evaluation in fouling study with cleaning, Frontiers of Environmental Science & Engineering (2022). DOI: 10.1007/s11783-022-1550-7