Specialists at the University of Bologna and Electrolux have as of late fostered another automated framework that could help people with one of their most regular regular tasks, doing clothing. This framework, presented in a paper distributed in SpringerLink’s Human-Friendly Robotics, was effectively prepared to embed things and get them from the clothes washer once a washing cycle is finished.

“Our new venture is the consequence of a joint effort between an industry accomplice, Electrolux, and the University of Bologna,” Gianluca Palli, one of the analysts who did the review, told TechXplore. “There was an interest from our industry accomplice, Electrolux, to create and send robotized clothing control into their homegrown apparatus test research facility, to speed the test and assessment of new items. This premium is propelled by the way that sending automated frameworks might actually help them in setting aside time and cash, by working test and approval all day, every day with negligible to no human mediation.”

The University of Bologna’s Laboratory of Automation and Robotics (LAR) has been leading broad explorations, zeroing in on mechanical control. Throughout recent years, analysts at this lab have presented various promising frameworks, including automated hand planning and novel approaches for switchgear wiring and control of deformable articles.

“Our industrial partner, Electrolux, was interested in developing and using robotized laundry manipulation in their home appliance test facility to speed up the testing and assessment of new goods. This enthusiasm arises from the notion that implementing robotic systems might help businesses save time and money by running test and validation operations 24 hours a day, seven days a week with little to no human participation.”

Gianluca Palli

“This matching interest among Electrolux and our lab prompted a cooperation that was formally sent off in 2017,” Palli said. “The principal objective of this cooperative task, including our new paper, was to create and assess a mechanical framework (insight pipeline and control calculations) to robotize clothing activities.”

The objective of recent exploration endeavors by LAR and Electrolux is to ultimately supplant human administrators at clothing cleaning stores and administrative offices with completely independent portable mechanical arms. This is a long way from a simple errand, as garments are exceptionally deformable, and robots regularly battle to deal with deformable articles effectively.

For an automated framework, doing clothing involves a few stages. These means incorporate identifying garments that should be washed, getting them, embedding them into the clothes washer, deciphering the data on the clothes washer’s showcase, and changing the settings on the machine to play out the ideal washing cycle.

Bedada, Ahmadli, and Palli contributed to this work.

“Guaranteeing the effective inclusion of clothing and recuperation picking from the drum entryway locale on the off chance that huge garments remain somewhat out of the clothes washer is likewise fundamental for the outcome of the proposed framework,” Palli said.

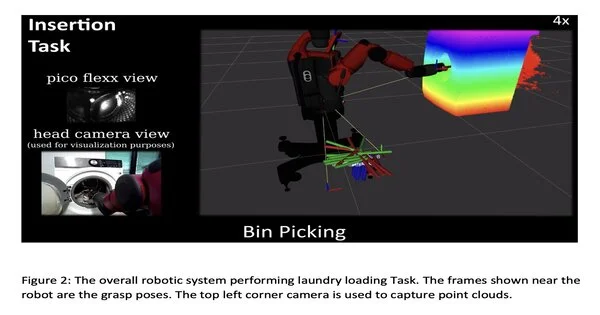

To work on their automated situation’s capacity to get a handle on and control things of dress and other material things, the specialists fostered a pointcloud-based insight calculation. This calculation can identify wrinkles on a fabric-based surface, figure spline bends along the kink like construction, and gauge the ideal for getting a handle on outlines.

“To work on the graspability of articles without any kinks, we additionally assessed a mass location approach along with handle present quality positioning, which distinguishes ideal postures,” Palli said. “We likewise fostered a profound learning-based clothes washer UI location and understanding calculation, which permits us to computerize the automated clothing activity completely.”

After they fostered their automated framework and its different parts, the specialists assessed its adequacy in a progression of tests. They used two mechanical stages they developed, the Tiago and Baxter robots, as well as an AEG clothes washer, in these tests.

“Our exploration shows that the issue of computerized clothing activity wasn’t examined in its full extension in writing,” Palli said. “This is the first time the issue of completely robotized clothing cycle activity was examined in the entirety of its perspectives immediately, including handle achievement, show acknowledgment, and mechanical impact aversion during collaboration.” Moreover, we were additionally ready to create and examine a human-like material, getting a handle on technique by focusing on kinks and masses that were registered from a live point cloud caught with a 3D Time of Flight (ToF) camera.

Later on, the mechanized clothing framework created by this group of analysts could be executed and tried in certifiable settings, to assess its exhibition in genuine settings. While in the starting tests, the framework accomplished promising outcomes, the analysts currently plan to chip away at it, to work on its generalizability and its capacity to deal with material things further.

“There are two proposed future examination headings,” Palli added. “The principal line of augmentation is to assess profound brain networks for the errand of flaw recognizable proof handling identification.” This will permit further speculation on the recently evolved vision calculations. The second area of expansion is to completely convey the proposed framework in a modern situation and possibly evaluate the monetary and different advantages acquired from this mechanical framework. We realize that our industry accomplice will lead further work toward this path. “