Another strategy to treat sewage can effectively switch extra ooze over completely to biogas, a development that could be useful to networks in bringing down their waste treatment costs while aiding the climate.

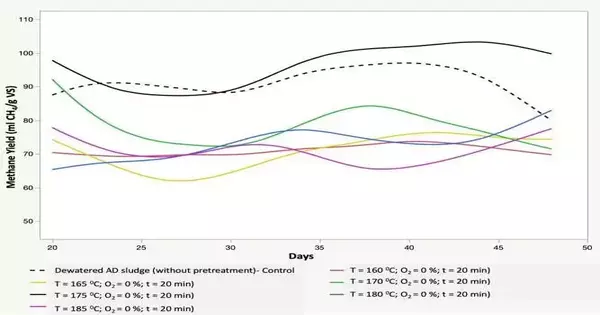

detailing in the diary, squandering On the board, a Washington State College research group tried a pretreatment innovation, adding an additional move toward common medicines and utilizing oxygen-containing high-strain steam to separate sewage muck. They observed that they had the option to convert over 85% of the natural material to biogas, which can be utilized to create power, or move up to sustainable petroleum gas (RNG) for the flammable gas matrix or for nearby use.

Adding the new pretreatment step works on the anaerobic change of sewage muck at the wastewater treatment office from the flow under half the transformation rate, and they created 98% more methane, generally contrasted with momentum practice.

“It was demonstrated to be very effective, and that is extremely energizing,” said Birgitte Ahring, teacher in the Quality and Linda Voiland School of Compound Designing and Bioengineering, who drove the work. “This can be relevant and something we could start to investigate in Washington State.” “Not squandering waste but rather utilizing its true capacity rather enjoys significant benefits.”

“It was shown to be extremely efficient, and that’s very exciting. This can be applicable and something we could begin to explore in Washington state. Not wasting waste but using its potential instead has major advantages.”

Birgitte Ahring, professor in the Gene and Linda Voiland School of Chemical Engineering and Bioengineering

Sewage muck isn’t a sought-after item. About a portion of the wastewater treatment plants in the U.S. utilize anaerobic absorption to lessen this waste, yet the cycle where organisms separate the waste is wasteful. The extra ooze, called biosolids, by and large winds up in landfills.

Wastewater treatment offices likewise utilize a lot of power to clean up city wastewater. They are many times the biggest client of power in a little local area.

“In the event that they could make their own power or, for a portion of the huge plants, make sustainable petroleum gas and add it to the flammable gas matrix, then they could lessen the utilization of non-renewable energy sources.” “Here we are starting to move into the possibility of a round economy,” said Ahring, who is likewise an employee in the Bioproducts, Sciences, and Designing Lab at WSU Tri-urban communities.

For their review, the WSU research group treated the muck at high temperature and strain, with oxygen added before the anaerobic absorption process. The modest quantity of oxygen under the high-tension circumstances acts as an impetus to separate the polymers in the material.

The WSU analysts have been reading up on this pretreatment cycle for a long time, utilizing it to separate straw and woody materials. They didn’t know the cycle would work with the different pieces of sewage sludge, like lipids and proteins, yet they were decidedly amazed.

“This isn’t an innovative arrangement,” Ahring said. “In reality, an answer can be helpful even with a limited scope.” “The proficiency must be high, or probably you can’t warrant adding the additional expenses for the cycle.”

The innovation could be especially useful for more modest networks, of which large numbers are encouraged to lessen squander and their environmental influence, she added.

The WSU group is working with Clean-Vantage, a Richland-based company focused on clean innovation and new business dynamics in the pretreatment region, as well as with the Pacific Northwest Public Lab (PNNL), which is doing a techno-monetary examination of the new cycle.

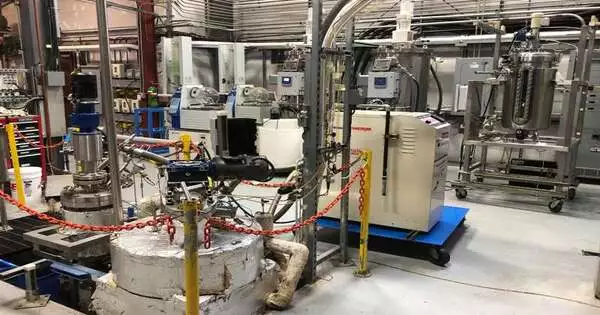

The analysts are currently increasing the work in their pilot office situated at WSU Tri-urban Communities to additionally illustrate the cycle. They are likewise concentrating on the most proficient method to effectively convert the biogas into additional important sustainable petroleum gas by a new bioprocess. While the biogas can be utilized to create power, delivering sustainable flammable gas could permit rustic networks to create nearby transportation fuel for filling their civil vehicles.

More information: Nalok Dutta et al, Improved valorization of sewage sludge in the circular economy by anaerobic digestion: Impact of an innovative pretreatment technology, Waste Management (2022). DOI: 10.1016/j.wasman.2022.09.035