Mid-year is practically here, when many individuals attempt to beat the intensity. In any case, running climate control systems continually can be costly and inefficient. Presently, analysts detailing in the ACS journal Nano Letters have planned a lightweight froth produced using wood-based cellulose nanocrystals that reflects daylight, transmits assimilated heat, and is thermally protected. They recommend that the material could decrease structures’ cooling energy needs by in excess of a third.

In spite of the fact that researchers have created cooling materials, they have burdens. A few materials that latently discharge heat let a ton of intensity through to structures under the immediate, noontime sun of the mid-year months. Furthermore, different materials that reflect daylight don’t function admirably in a sweltering, damp or overcast climate. In this way, Yu Fu, Kai Zhang, and partners needed to foster a powerful material that could reflect daylight, inactively discharge intensity, and hold delinquent intensity back from going through.

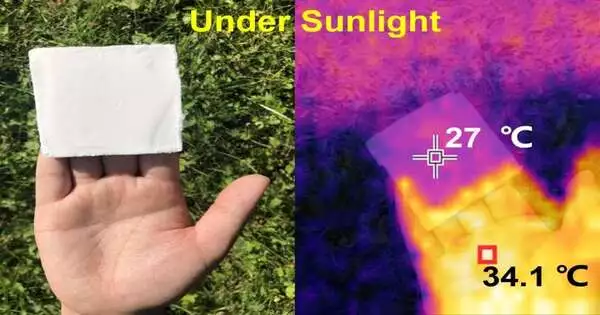

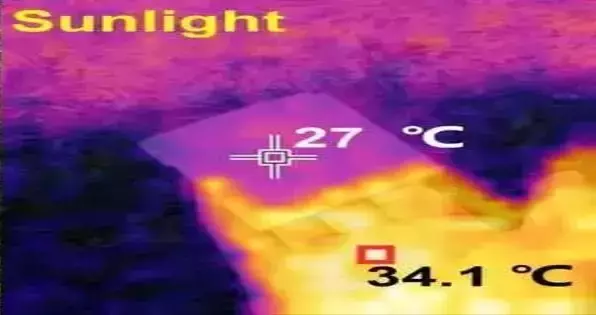

To produce a cooling material, the scientists associated cellulose nanocrystals with a silane span, prior to freezing and freeze-drying the material under a vacuum. This cycle upward adjusted the nanocrystals, making a white, lightweight froth that reflected 96% of apparent light and discharged 92% of consumed infrared radiation.

Whenever it was set over an aluminum foil-lined box sitting outside in the early afternoon, the material kept the temperature inside the container 16 degrees F cooler than the temperature outside it. Likewise, the material kept within the container was 13 degrees F cooler when the air was muggy. As the cellulose-based froth was compacted, its cooling capacity diminished, revealing tunable cooling properties.

The group determined that putting the froth on the rooftop and outside dividers of a structure could decrease its cooling energy needs by a normal of 35.4%. The scientists say that the innovation could be applied in a wide scope of conditions since the wood-based cellulose froth’s exhibition can be tuned relying upon weather patterns.

A gigantic piece of energy usage goes towards warming and cooling homes and structures, so it means a lot to track down better approaches to latently direct temperature. Engineers in China and Germany have fostered another wood-based foam that can radically cool structures, to a certain extent that can be effortlessly tuned.

Cooling is compelling, yet it’s not the most harmless method for chilling. Lately, researchers have been creating methods that don’t chug such a lot of power, including super-white paints or mirror coatings that reflect daylight, and radiative cooling frameworks that transmit a structure’s intensity as infrared waves high up, where it goes straight through the environment and vents into the cold of space.

However, the adequacy of these frameworks can change under various circumstances. Intelligent coatings, for example, can in any case allow in heat on the off chance that it’s especially hot or moist, while radiative cooling doesn’t fill in either, assuming it’s shady. The degree of cooling can likewise be difficult to tune.

Presently, researchers at the University of Göttingen and Nanjing Forestry University have made another material that they say takes care of a portion of these issues. It’s basically a frothy substance put together with wood that reflects daylight, goes about as warm protection, and discharges consumed heat once more into the air.

It’s made from cellulose nanocrystals, associated with an extension of silane, which is then freeze-dried into a white, lightweight froth. The end result reflects 96% of the apparent light from the Sun and produces 92% of the infrared radiation it ingests.

To test the material’s cooling capacities, the specialists put it over a case fixed within with aluminum foil, and sat it in direct sunlight around early afternoon. The material kept the crate 16.5 °F (9.2 °C) cooler than the air outside, and, surprisingly, in a muggy climate, it actually kept the inside 13.3 °F (7.4 °C) cooler. When expanded to line the roof and dividers of a structure, analysts estimate that it could reduce energy requirements for cooling by 35% on average.

Most intriguingly, the froth’s cooling power diminished assuming it was compacted. That could seem like a burden, but the group proposes that crushing the froth could be a helpful method for fine tuning how much cooling is expected by the climate or climate.

The scientists say that the new cooling froth could ultimately make way for warm directing materials that are harmless to the current ecosystem yet additionally cut the expense of energy utilized for cooling.

The exploration was published in the diary Nano Letters.

Source: The American Chemical Society