A KAIST research group has fostered an enemy of icing and de-icing film covering innovation that can apply the photothermal impact of gold nanoparticles to modern locales without the requirement for warming wires, intermittent splash or oil covering of liquid catalyst substances, or substrate plan changes.

The gathering led by Teacher Hyoungsoo Kim from the Division of Mechanical Designing (Liquid and Connection Point Research Center) and Teacher Dong Ki Yoon from the Branch of Science (Delicate Material Get Together Gathering) uncovered that they have fostered a unique method that can consistently design gold nanorod (GNR) particles in quadrants through straightforward dissipation and have utilized this to foster an enemy of icing and de-icing surfaces.

The review is named “Plasmonic Metasurfaces of Cellulose Nanocrystal Networks with Quadrants of Adjusted Gold Nanorods for Photothermal Against Icing” and is distributed in the journal Nature Correspondences.

“This technique works on both flexible and plastic materials. By applying it to exterior materials and films, it can generate its own heat energy, resulting in significant energy savings through voluntary thermal energy harvesting in a variety of applications such as cars, aircraft, and windows in residential or commercial spaces where frosting is a major issue during the winter.”

Professor Hyoungsoo Kim from the Department of Mechanical Engineering (Fluid & Interface Laboratory).

Numerous researchers lately have attempted to control substrate surfaces through different covering procedures, and those including the design of practical nanomaterials stand out. Specifically, GNR is viewed as a promising competitor nanomaterial for its biocompatibility, compound dependability, moderately straightforward combination, and its steady and remarkable property of surface plasmon reverberation.

To boost the presentation of GNR, it is essential to achieve high consistency during film testimony and an elevated degree of bar arrangement. Nonetheless, accomplishing the two standards has, up to this point, been a troublesome test.

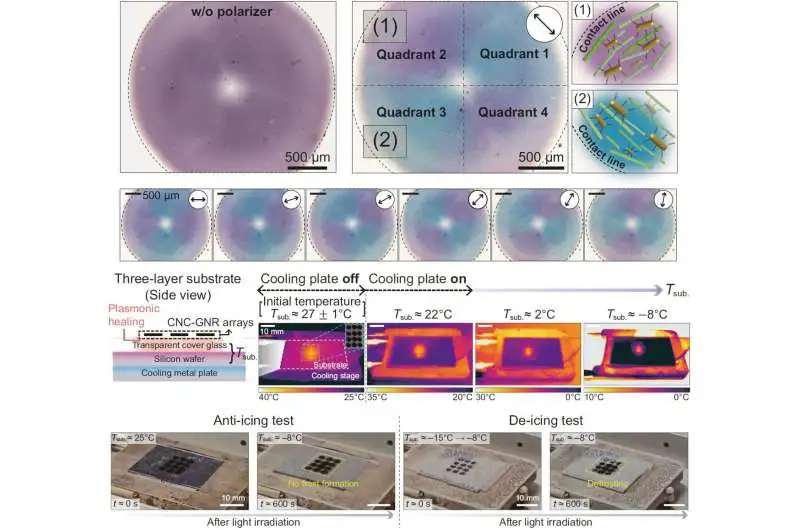

Optical and warm execution assessment consequences of gold nanorod film and exhibition of plasmonic radiators against icing and de-icing. Credit: Nature Interchanges (2023). DOI: 10.1038/s41467-023-43511-9

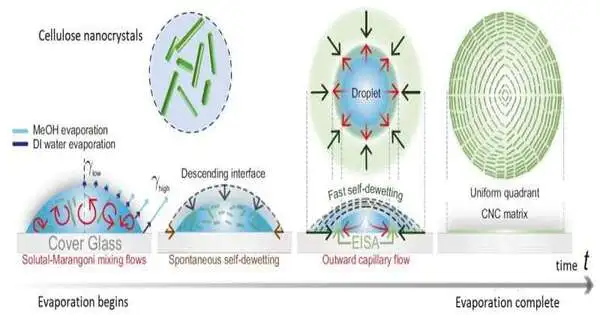

To settle this, the joint exploration group used cellulose nanocrystal (CNC), a cutting-edge utilitarian nanomaterial that can without much of a stretch be extricated from nature. By co-gathering GNR on CNC quadrant layouts, the group could consistently dry the film and effectively get a GNR film with a uniform arrangement in a ring shape.

Contrasted with existing espresso ring films, the profoundly uniform and adjusted GNR film created through this exploration showed upgraded plasmonic photothermal properties, and the group demonstrated the way that it could complete the enemy of icing and de-icing capabilities by just illuminating light in the apparent frequency range.

Teacher Kim said, “This method can be applied to plastic as well as adaptable surfaces. By utilizing it on outside materials and movies, it can produce its own intensity energy, which would extraordinarily save energy through deliberate nuclear power collection across different applications, including vehicles, airplanes, and windows in private or business spaces, where icing turns into a difficult issue in the colder time of year.”

Teacher Yoon added, “This exploration is huge in that we can now openly design the CNC-GNR composite, which was beforehand challenging to make into films, over an enormous region. We can use this as an enemy of icing material, and if we somehow happen to exploit the plasmonic properties of gold, we can likewise utilize it like stained glass to brighten glass surfaces.”

More information: Jeongsu Pyeon et al, Plasmonic metasurfaces of cellulose nanocrystal matrices with quadrants of aligned gold nanorods for photothermal anti-icing, Nature Communications (2023). DOI: 10.1038/s41467-023-43511-9