NIST researcher Gary Zabow had never planned to involve treats in his lab. He’d even tried covering tiny attractive dabs in solidified lumps of sugar—basically, hard treats—and sending these sweet bundles to partners in a biomedical lab if all else failed.The sugar breaks up effectively in water, liberating the attractive dabs for their examinations without abandoning any unsafe plastics or synthetics.

By some coincidence, Zabow had left one of these sugar pieces, implanted with varieties of micromagnetic dabs, in a container, and it did what sugar does with time and intensity—iit softened, covering the lower part of the recepticle in a gooey wreck.

“Don’t sweat it,” he thought. As is customary, he would simply break up the sugar and throw it away.But this time, when he washed out the container, the microdots were no more. Yet they weren’t exactly absent; rather than delivering into the water, they had been moved onto the lower part of the glass, where they were projecting a rainbow reflection.

“The semiconductor industry has spent billions of dollars improving the printing procedures that are used to make the chips that we rely on. Wouldn’t it be great if we could use some of these technologies to extend the reach of those prints with something as simple and inexpensive as a piece of candy?”

Scientist Gary Zabow

“It was those rainbow colors that truly amazed me,” Zabow says. The tones showed that the varieties of microdots had held their own.

This sweet wreck gave him a thought. At any point, might normal table sugar be accustomed to carrying the force of CPUs to new and flighty surfaces? Zabow’s discoveries on this potential exchange printing process were distributed in Science on Nov. 25.

Semiconductor chips, micropatterned surfaces, and gadgets all depend on microprinting, the most common way of putting exact yet tiny examples (millionths to billionths of a meter wide) onto surfaces to give them new properties. Generally, these small labyrinths of metals and different materials are imprinted on flat wafers of silicon. Yet, as the opportunities for semiconductor chips and savvy materials grow, these complex, small examples should be imprinted on new, flighty, non-level surfaces.

Straightforwardly printing these examples on such surfaces is precarious, so researchers move prints. There are adaptable tapes and plastics that can finish the job (for example, using clay to get newsprint), but these solids can have trouble adjusting to sharp bends and corners when the print is easygoing down.They could likewise abandon plastics or different synthetics that could be difficult to eliminate or be risky for biomedical purposes.

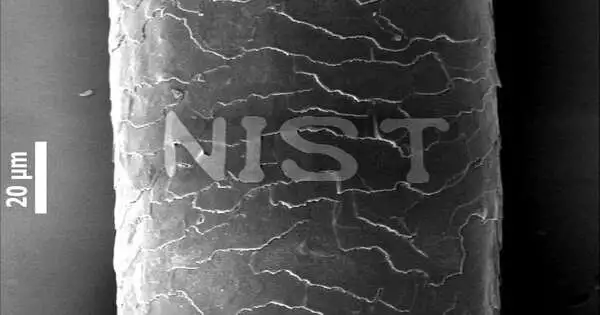

Utilizing sugar and corn syrup (i.e., candy), scientist Gary Zabow moved “NIST” in gold letters onto a human hair.

There are fluid methods in which the exchange material is pushed through the objective surface while drifting on the outer layer of water. Yet, that can be precarious as well; with an openly streaming fluid, it tends to be difficult to put the print exactly where you need it on another surface.

Yet, as Zabow shockingly found, a basic mix of caramelized sugar and corn syrup can get the job done.

When broken up in a modest quantity of water, this sugar blend can be poured over micropatterns on a level surface. When the water vanishes, the candy solidifies and can be lifted away with the example inserted. The candy with the print is then positioned over the new surface and softened. The sugar/corn syrup mix keeps a high thickness as it softens, allowing the example to keep up with its plan as it streams over bends and edges. Then, utilizing water, the sugar can be washed away, abandoning only the example.

Using this method, known as REFLEX (REflow-driven Adaptable Xfer), microcircuit examples could be moved like a stencil, allowing researchers or manufacturers to precisely engrave and fill the materials they require.On the other hand, designed materials could be moved from their unique chip onto strands or microbeads for potential biomedical or microrobotics studies or over sharp or bended surfaces inside new gadgets.

The method demonstrated fruitfulness for a huge scope of surfaces, including imprinting onto the sharp mark of a pin and composing “NIST” in microscale gold lettering onto a solitary strand of human hair. In another model, 1-micrometer-wide attractive plates were effectively moved onto the floss fiber of a milkweed seed. Within the sight of a magnet, the attractively printed fiber responded, showing the exchange had worked.

There’s something else to investigate with REFLEX, yet this cycle could open additional opportunities for new materials and microstructures across fields from gadgets to optics to biomedical design.

“The semiconductor business has burned through billions of dollars idealizing the printing methods to make the chips we depend on,” Zabow says. “Couldn’t it be great if we would use a portion of those innovations, growing the span of those prints with something as basic and cheap as a sweet?”

More information: G. Zabow, Reflow transfer for conformal three-dimensional microprinting, Science (2022). DOI: 10.1126/science.add7023. www.science.org/doi/10.1126/science.add7023

Journal information: Science