Joel Berkson, a third-year doctoral understudy in the University of Arizona’s James C. Wyant College of Optical Sciences and Steward Observatory, has fostered another way of unequivocally estimating the surfaces of radio-receiving wires, which are utilized to gather and concentrate radio waves for cosmology and satellite correspondence.

These dish-formed receiving wires, similar to the ones portrayed in the 1997 film “Contact” featuring Jodie Foster, should be fabricated with an incredibly elevated degree of precision to function admirably. To guarantee their exactness, engineers measure the recieving wire surfaces utilizing metrology, a strategy that applies the study of estimation to assembling, instrumentation, and alignment processes.

Individuals generally need to make bigger, more precise receiving wires for radio telescopes, and a greater number of them, Berkson said. In the event that we can’t sort out better ways of making them quicker and more exact, the expense and time it takes to quantify each surface to guarantee its quality will be restrictive.

“People always want to make larger, more accurate antennas for radio telescopes, and more of them. If we can’t figure out better ways to make them faster and more accurate, the cost and time it takes to measure each surface to ensure its quality will be prohibitive.”

Berkson said

Existing strategies for estimating the bended surfaces of radio receiving wires and telescope mirrors include putting stickers across the radio wire or mirror surface and then utilizing cameras to investigate the surface by checking the stickers out. Different techniques include actually testing the surface with a direction-estimating machine. These methods are limited to estimating the number of focuses displayed by the stickers or contacted by an actual test; it is a manual, slow, and frequently expensive cycle.

To make things much more convoluted, here and there the surfaces don’t come out flawlessly and should be fixed and estimated once more, converting into more cash and time spent.

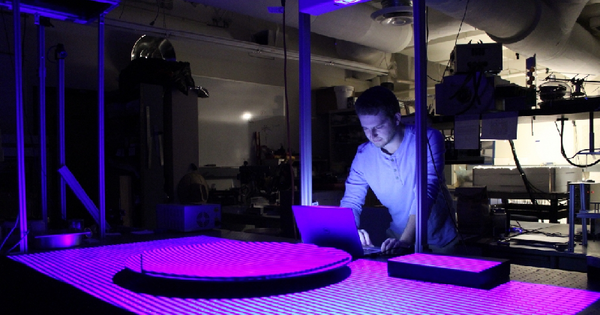

Berkson’s creation kills the requirement for stickers or actual touch. The strategy he created utilizes a blend of laser projectors and cameras to make a 3D model of the surface. By delivering the real surface shape as a PC model, the new cycle beats one more constraint of the old techniques; as opposed to being restricted to estimating many focuses, it takes into consideration the estimation of millions of focuses on a surface.

Tech Launch The University of Arizona, the UArizona office that popularizes innovations originating from college research, has worked with Berkson to patent the innovation in the interest of the college and permit it to Berkson’s startup, Fringe Metrology.

It was especially remunerating to see Joel’s work, imagining a way to deal with addressing a genuine test and changing it into a rich business arrangement, said Bruce Burgess, overseer of adventure advancement at TLA. “Joel perceived the abundance of assets TLA offers specialists and rushed to work with our group.”

“A great number of frameworks out there today are discovery frameworks and need customization to be valuable in the field,” Berkson said. “Our own is one framework that can be effectively designed to quantify surfaces of various shapes and sizes. You can’t do that with some other current advancements out there. “

Whenever Berkson acknowledged that existing metrology frameworks require the utilization of stickers to make estimations, he was propelled to adopt a critical thinking strategy to work on the cycle.

Stickers have been utilized in all cases and are the norm and very much trusted,” he expressed, “but as the interest for additional exact and confounded surfaces builds, the estimation prerequisites similarly increment.” The ongoing techniques are not generally as great as individuals need and should have the option to propel these frameworks. “

Working with his co-designer, Justin Hyatt, a senior examination partner at Steward Observatory, Berskon started fostering the innovation with financing from the National Science Foundation to propel current techniques for radio telescope fabricating. He was a member of the TLA commercialization group, which collaborated with him to promote licensed innovation for the creation.Berkson then began Fringe Metrology, authorized the development of UArizona, and has started fabricating a business around it.

The startup is creating particular frameworks for an assortment of surface metrology applications, but first it will zero in on the careful estimations required for the production of radio telescope boards.

“The radio telescopes like the ones you find in the film ‘Contact’ are exceptionally precise and costly to fabricate, and they should be impeccably molded to work accurately,” Berkson said. “The organization will first focus on these high-esteem clients to foster the underlying go-to-showcase item.”

As Berkson centers around developing his business, he trusts innovation can offer an answer to the ongoing constraints in radio telescope fabricating and add to the advancement of the business.

Finally, he said, “I might want to see speedier, less expensive, and greater estimating frameworks in each lab.”