Lithium-particle batteries (LIBs), battery-powered batteries that store energy by means of the reversible decrease of lithium particles, are utilized to control incalculable gadgets and innovations, from workstations and cell phones to electric vehicles. Although LIBs have a number of advantages over other battery technologies, the distances that electric vehicles can travel before needing to be recharged are limited by their current energy densities.

Concentrates show that the development of the strong electrolyte interphase (SEI), a layer that structures on the anode inside battery cells, can consume a lot of lithium particles. This lowers a battery’s energy density by negatively affecting its initial Coulombic efficiency—the efficiency with which electrons are transferred prior to their first cycle.

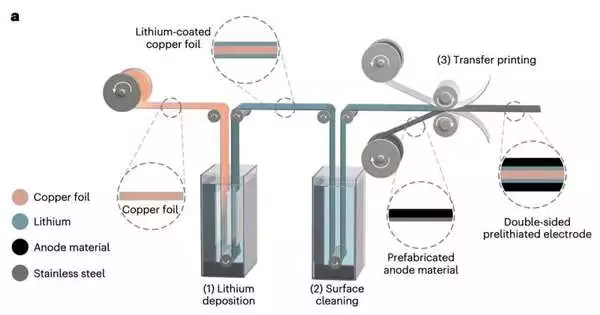

A technique that could assist with checking this impact by decreasing the deficiency of dynamic lithium inside LIBs and consequently helping their energy thickness is prelithiation. Pre-treating the electrodes and adding lithium to the battery cell prior to its first operation cycle make up the core of this approach.

“We developed a roll-to-roll electrodeposition and transfer-printing system for continuous prelithiation of LIB anodes. Pre-manufactured anodes might be entirely transfer-printed onto electrodeposited lithium metal via roll-to-roll calendering. “Interfacial shear and compressive stress were found to be related to interface separation and adhesion during transfer printing, respectively.”

Cheng Yang, Huachun Ma and their colleagues wrote in their paper.

A promising method for large-scale prelithiation of anodes for LIBs has recently been developed by researchers at Tsinghua University. Their prelithiation technique, presented in Nature Energy, depends on move printing, a strategy to print designs onto a middle medium and then apply them to the last substrate or material.

“A financially savvy prelithiation technique with excellent modern similarity is desperately required,” Cheng Yang, Huachun Mama, and their partners wrote in their paper. “We fostered a roll-to-move electrodeposition and move printing framework for persistent prelithiation of LIB anodes. By roll-to-roll calendering, pre-made anodes could be completely imprinted onto electrodeposited lithium metal. Interfacial shear and compressive stress were linked to interface separation and adhesion during transfer printing, respectively.

The scientists assessed their methodology by running a series of reenactments and electrochemical tests. They found that it performed amazingly well, as it could further develop the underlying Coulombic efficiencies of both graphite-based and silicon/carbon-based cathodes for LIBs, raising them to practically 100 percent.

Outstandingly, as well as empowering these high beginning colonic efficiencies, the group’s methodology worked on the dependability of the SEI films made on anodes. Yang, Ma, and their colleagues discovered that prelithiated electrodes significantly increased fuel cell energy density when used in conjunction with NMC and LFP cathodes, two of the most widely used LIB cathodes.

“With the effortless exchange printing prelithiation, high starting Coulombic efficiencies of 99.99% and 99.05% were accomplished in graphite and silicon/carbon composite cathode half cells, separately,” Yang, Mama, and their partners wrote in their paper. “The underlying Coulombic efficiencies and energy densities in full cells were seen to be essentially improved with the prelithiated cathodes. Roll-to-move printing gives a superior presentation and is controllable, versatile, and industry-versatile in prelithiation in LIBs.”

The exchange printing technique presented by Yang, Mama, and their partners has up to this point accomplished extremely encouraging outcomes, recommending that it could ultimately empower the huge scope and dependable prelithiation of anodes for LIBs. Their paper could soon rouse other exploration groups to devise comparable methodologies aimed at further developing the energy thickness of LIBs. Together, these strategies might make it easier for more people to buy electric cars.

More information: Cheng Yang et al, Roll-to-roll prelithiation of lithium-ion battery anodes by transfer printing, Nature Energy (2023). DOI: 10.1038/s41560-023-01272-1.