Prof. Becky Peterson at the College of Michigan leads a group that has fostered a versatile, manufacturable strategy for growing slim film semiconductors (TFTs) that work at the lowest conceivable voltage. This is especially significant for TFT mixing with the present silicon reciprocal metal-oxide semiconductors (CMOS), which are utilized in by far the majority of coordinated circuits.

“We’re basically fostering a less muddled gadget that works at lower voltage,” said ECE Ph.D. understudy Tonglin (Tanya) Newsom, who is the first creator on the paper. “With this lofty sub-edge swing gadget, we could altogether bring down the energy dispersal of our hardware, meaning there’s less energy misfortune.” “This could help every individual who utilizes electronic gadgets.”

TFTs empower the activity of current showcases, acting as switches that control the light at every individual pixel. Exchanging effectively between the on and off states considers lower voltage activity and results in a more energy-efficient framework. One of the key assembling difficulties to achieving a profoundly effective switch is the necessity of a perfect connection point between the different material layers inside the TFT. A perfect connection point implies electrons can stream into the channel to turn the pixel “on” or “off” without getting caught.

“We’re essentially creating a simpler device that runs at a lower voltage. We could greatly reduce the energy dissipation of our circuitry with this steep sub-threshold swing device, resulting in less energy loss. This could be beneficial to everyone who utilizes technological devices.”

ECE Ph.D. student Tonglin (Tanya) Newsom, who is first author on the paper.

“The key innovation that we were attempting to create is a super-perfect connection point between the semiconductor and the door cover, so the exchanging system between the on and off states would be sharp,” Peterson said. “We had the option to accomplish exchanging at the quickest rate conceivable, as per key actual cutoff points at room temperature.”

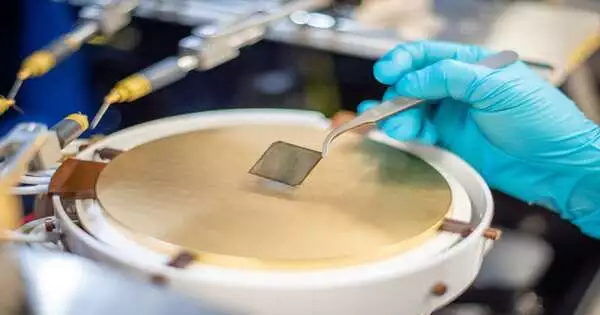

To do this, Peterson’s group cooperated with Mechanical Designing Teacher Neil Dasgupta, with whom they fostered a nuclear layer testimony innovation for zinc tin oxide, which is a wide bandgap semiconductor that can be utilized for electronic and energy gadgets, like TFTs, flexible sensors, and sun-based cells. Peterson’s group took this innovation one step further by straightforwardly coordinating the nuclear layer affidavit processes for two different key pieces of the semiconductor—the door capacitor and the semiconductor channel.

“We obtain the best outcomes by saving the two layers consecutively inside a similar device, without breaking vacuum,” Peterson said. “This approach shows a clear strategy to accomplish ideal TFT execution.”

Peterson’s group centered around formless oxide semiconductors, which are a class of materials that are marketed in displays and empower us to control pixels separately. They’re significant for accomplishing low-power activity, high-pixel-thickness screens, contact screens, and haptic showcases, which create material impacts—like vibrations—for various applications, including wearables and AR/VR gadgets.

“I really trust more individuals will become keen on doing this sort of key science and designing,” Newsom said, “on the grounds that this work isn’t just about finding additional opportunities; it’s tied in with further developing innovation to help the world.”

The paper, “59.9 mVdec-1 Subthreshold Swing Accomplished in Zinc Tin Oxide TFTs With In Situ Nuclear Layer Kept Al2O3 Door Cover,” was selected as an IEEE Electron Gadget Letters Manager’s Pick.

More information: Tonglin L. Newsom et al, 59.9 mV·dec Subthreshold Swing Achieved in Zinc Tin Oxide TFTs With In Situ Atomic Layer Deposited AlO Gate Insulator, IEEE Electron Device Letters (2022). DOI: 10.1109/LED.2022.3219351