Energy specialists and material researchers are consistently attempting to make safe battery advancements that display higher energy densities and efficiencies, alongside longer life cycles. Since lithium-ion batteries (LiBs) are one of the most widely used battery technologies, a lot of current research focuses on improving cathodes, which are the positive electrodes inside battery cells.

The majority of LiB cathodes that have been proposed have morphologies that are polycrystalline, indicating that they are made up of multiple distinct crystalline particles. Although these cathodes are simple to manufacture on a large scale, they are prone to cracking during battery cycling. This can isolate some active materials within them, expose them to liquid electrolytes, and potentially lower the performance of the battery.

This crucial limitation of polycrystalline cathodes may be overcome by single-crystal cathodes, which are based on single grain-sized crystalline particles. However, it has been difficult to consistently manufacture them using scalable processes up to this point.

“The production of single-crystalline cathodes with high phase purity, good electrochemical performance, and scalability remains challenging due to the temperature range available to prevent lithium evaporation, lattice defects, and particle agglomerations,” says the report.

Moonsu Yoon, Yanhao Dong and their colleagues.

A new, scalable method for synthesizing single-crystalline cathodes with high phase purity and good electrochemical performance has recently been developed by researchers at the Ulsan National Institute of Science and Technology (UNIST) in South Korea and the Massachusetts Institute of Technology (MIT). This method of using molten Li salts to corrode the boundaries between smaller grains and transform them into larger crystals to create single-crystal layered cathodes was first presented in Nature Energy.

Moonsu Yoon, Yanhao Dong, and their colleagues told Tech Xplore that the production of single-crystalline cathodes with high phase purity, good electrochemical performance, and scalability “remains challenging” due to limitations imposed by the temperature range that can be used to prevent lithium evaporation, lattice defects, and particle agglomerations.

“We invent a new mechanochemical activation process that offers a general solution to the conundrum of synthesizing coarse single-crystal cathodes with Li-/Mn-rich or Ni-rich chemistry,” the statement reads. “This is different from the equipment- and energy-intensive, long-duration mechanochemical routes that are difficult to scale up.”

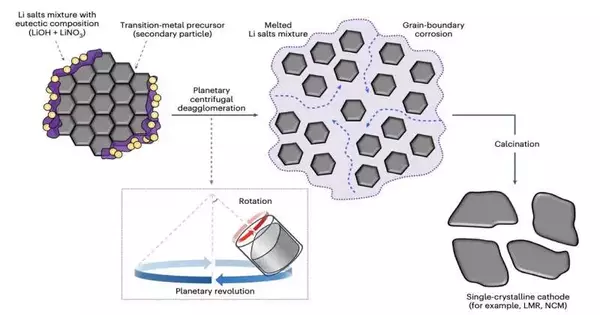

Yoon, Dong, and their colleagues propose a planetary centrifugal deagglomeration method for synthesizing single-crystal cathodes. The team demonstrated that this method could scale up the production of single-crystal cathodes from readily available commercial materials.

In their paper, Yoon, Dong, and their colleagues wrote, “Our approach is based on interfacial reactive wetting, mediated by transient eutectic salts in situ melted by moderate mechanical agitations, to form a colloidal suspension of nanosized oxides dispersed in liquified lithium salts.” It effectively deagglomerates the polycrystalline precursors, repackages the crystals, and homogenizes the lithium-salt distribution, allowing for simpler particle coarsening into the single-crystalline morphology with enhanced electrochemical performance later on.”

Notably, the researchers were able to achieve the desired reaction with just the molten Li salts they used. Additionally, their synthesis strategy is simple to integrate with existing cathode manufacturing procedures, which could make its widespread adoption much easier.

The findings of this recent study may soon be used as a basis for the creation of additional strategies for the production of high-performance LiB single-crystal cathodes. Together, these methods have the potential to help overcome the limitations of current cathodes and contribute to the development of more advanced battery solutions.

More information: Moonsu Yoon et al, Eutectic salt-assisted planetary centrifugal deagglomeration for single-crystalline cathode synthesis, Nature Energy (2023). DOI: 10.1038/s41560-023-01233-8.