Current optoelectronic devices have been overshadowed by non-renewable energy sources like coal, oil, and natural gas, which may be partially explained by ongoing difficulties in the production of solar cells.

Now, using PEDOT:PSS/silicon heterojunction solar cells, researchers at Kyoto University may have discovered a more environmentally friendly solution with improved performance. As opposed to conventional silicon-only solar cells, this hybrid type is made of organic and inorganic materials, which may simplify the manufacturing process.

Lead author Katsuaki Tanabe says, “We wanted to avoid manufacturing solar cells in vacuums and high-temperature processes, which require large and expensive equipment and a lot of time.

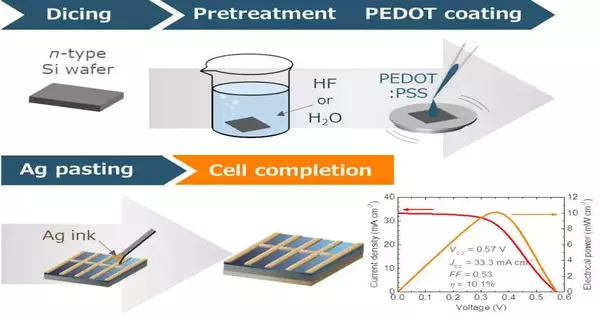

The team decided to fabricate solar cells from silicon wafers using only ambient temperature and pressure because they anticipated a difficult task. However, after enhancing the wafer processing conditions, their efforts were found to produce meritorious outcomes.

These polished wafers were divided into 8-mm square pieces before being coated with silver electrodes and PEDOT:PSS aqueous solution in various orders.

The author claims that “our strategy enabled us to achieve improved production speed at lower cost and with a power generation efficiency above 10%.”

According to Tanabe’s team, the widespread adoption of photovoltaic energy production may be facilitated by this new, more effective manufacturing process. In a variety of contexts, including education or emerging economies, this system may prove more useful.

Tanabe adds, “We will then concentrate on optimizing additive concentrations and impurity levels in our production, as well as other structural innovations.”

The findings have been released in the PNAS Nexus journal.

More information: Kazuya Okamoto et al, An all ambient, room temperature–processed solar cell from a bare silicon wafer, PNAS Nexus (2023). DOI: 10.1093/pnasnexus/pgad067