Plasmids have broad use in fundamental and applied science. These little, round DNA particles are utilized by researchers to bring new qualities into an objective life form. Notable for their applications in the creation of remedial proteins like insulin, plasmids are comprehensively utilized in the huge scope of creation of numerous bioproducts.

Nonetheless, planning and building plasmids remains one of the most tedious and serious strides in science research.

To address this, Behnam Enghiad, Pu Xue, and other University of Illinois Urbana-Champaign analysts at the Center for Advanced Bioenergy and Bioproducts Innovation (CABBI) have fostered an adaptable and robotized stage for plasmid planning and development called PlasmidMaker. Their work was recently distributed in Nature Communications.

“We aim to eventually make this technology available to all researchers at the other three Bioenergy Research Centers. If everything goes well, we intend to make it open to all scholars worldwide,”

Huimin Zhao

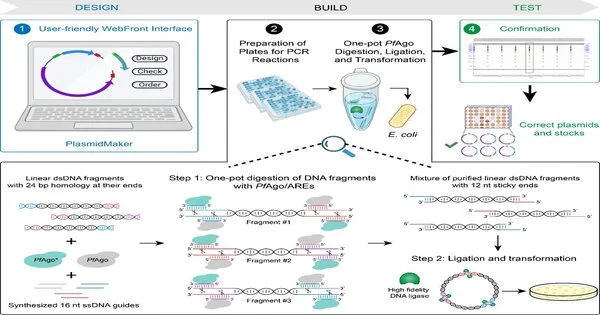

Making a plasmid begins with a plan. To support this plan cycle, PlasmidMaker has an easy to understand web connection with which scientists can instinctively picture and collect the ideal plasmid for their needs.

When the plasmid has been planned, it is submitted to the PlasmidMaker group, and a request for the plasmid is set at the Illinois Biological Foundry for Advanced Biomanufacturing (iBioFAB), where the plasmid will be fabricated. iBioFAB, situated at the Carl R. Woese Institute for Genomic Biology (IGB) on the U of I grounds, is a completely incorporated computational and actual foundation that upholds fast manufacture, quality control, and investigation of hereditary developments. It includes a focal automated arm that moves labware between instruments that perform unmistakable tasks like pipetting, brooding, or thermocycling.

Credit: Enghiad et al.

The plasmid construction process is robotized: tests are ready through polymerase chain reaction (PCR) and refinement, the DNA sequence is gathered and changed, and the plasmids are affirmed and frozen, all with minimal human inclusion.

Besides the robotization and accuracy managed by iBioFAB, the PlasmidMaker stage additionally spearheads another profoundly adaptable technique for gathering numerous DNA parts into a plasmid utilizing Pyrococcus furiosus Argonaute (PfAgo)-based counterfeit limitation chemicals (AREs).

Limitation catalysts have for quite some time been utilized in plasmid development as they can separate DNA particles at explicit successions of bases, called acknowledgment groupings. Nonetheless, these acknowledgement groupings are typically short, making them hard to work with. A short arrangement is probably going to happen on various occasions in a DNA particle, in which case the limitation chemical would make an excessive number of cuts.

Huimin Zhao, co-creator and the Steven L. Mill operator Chair of Chemical and Biomolecular Engineering (ChBE) at Illinois, said “In past DNA get together strategies, it would frequently be difficult to get hold of the right limitation compounds that can cut the plasmid and supplant the DNA sections.” “The PfAgo-based AREs offer more noteworthy adaptability and accuracy, as they can be modified to search out longer acknowledgment groupings at basically any site.”

With every one of the upgrades it offers that would be useful, the colleagues at CABBI, one of four U.S. Division of Energy-supported Bioenergy Research Centers across the United States, trust that PlasmidMaker will speed up the improvement of manufactured science for biotechnological applications.

“This device will be accessible to CABBI scientists, and we need to ultimately make it accessible to all analysts at the other three bioenergy research centers,” Zhao said. Assuming that things work out in a good way, we desire to make it accessible to all analysts all over.