An interdisciplinary group of scientists at the University of Alabama at Birmingham has fostered another plasma-empowered process that could restrict the multiplication of poisons from being inserted into a patient’s circulatory system. The group, led by Vinoy Thomas, Ph.D., academic partner in the UAB School of Engineering’s Department of Mechanical and Materials Engineering, as of late distributed discoveries in the ACS Applied Materials and Interfaces diary.

In the article, the writers make sense that a significant test of creating nanoparticle-changed biomedical embed material is to steadily connect metallic nanoparticles on various surfaces, especially polymer surfaces.

“For quite a long time, researchers have achieved a blend of metallic nanoparticles in watery arrangements utilizing both synthetic and organic (plant extricate) lessening specialists,” Thomas said. “The test of appending metallic nanoparticles is particularly troublesome in cases including hydrophobic polymeric biomaterials, which most polymeric biomaterials fall under.”

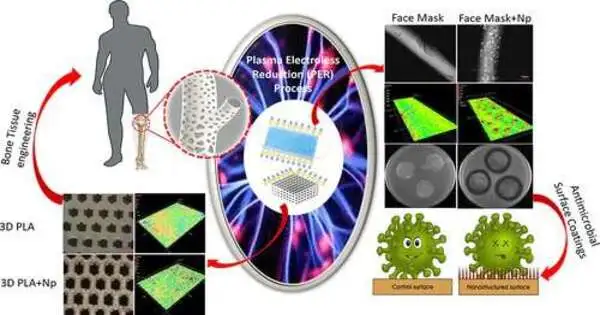

To address this test, Thomas and his group fostered a plasma-empowered process called plasma electroless decrease. The PER cycle permits scientists to store gold and silver nanostructures on various 2D and 3D polymer material surfaces, for example, cellulose paper, polypropylene-based facemasks, and 3D printed polymer frameworks.

“We predict that such consistent smaller 3D scaffold design would provide large-scale and more dependable 3D scaffold in vitro testing. This systematic optimization of producing homogeneous metal nanostructures on 3D scaffolds with cytocompatibility and probable antibacterial properties will be highly relevant and may have an impact on the future development of biocompatible scaffolds, particularly for osteomyelitis disease.”

Vinoy Thomas, Ph.D., associate professor in the UAB School of Engineering’s Department of Mechanical and Materials Engineering

“It is notable that there are harmfulness issues presented by the fast and untimely arrival of the metallic nanostructures from the embedded material into the circulatory system,” Thomas said. “This issue could be tended to simply by guaranteeing the stable securing of the metallic nanostructures on embedded surfaces.” This has motivated us to enhance our PER cycle by directing orderly and top-to-bottom examination of the grouping of the metallic forerunner followed by sonication wash before cell culture in vitro.

In Thomas’ review, his group had the option to effectively moor silver nanoparticles on the outer layer of 3D printed polymers with no quick delivery into the environmental factors. The group’s added substance producing skills likewise permitted them to plan more modest 3D framework wafers that will squeeze into the well of a 96-well plate.

“We guess that the plan of such a predictable and more modest 3D framework configuration would guarantee enormous scope and more dependable in vitro testing of 3D platforms,” Thomas said. “This methodical streamlining of making uniform metal nanostructures on 3D frameworks with cytocompatibility and potential antibacterial properties will be exceptionally important and might possibly have an effect on the future advancement of biocompatible platforms, particularly for osteomyelitis illness.”

It required two years for the group to foster the PER interaction, but the cycle is only one of a few viewpoints Thomas is contemplating concerning plasma.

“Plasma, the fourth issue condition,” he explained, “is a partially ionized gas that addresses one of the greener strategies for combining metallic nanoparticles in a fluid stage.” “It has colossal capacity in materials handling and to purify surfaces to forestall the spread of COVID-19 and other transferable sicknesses.”

More information: Vineeth M. Vijayan et al, Plasma Electroless Reduction: A Green Process for Designing Metallic Nanostructure Interfaces onto Polymeric Surfaces and 3D Scaffolds, ACS Applied Materials & Interfaces (2022). DOI: 10.1021/acsami.2c01195