Fringe photoinhibition (PPI) and direct laser composing (DLW) are lithography methods used to create complex 3D nanostructures that are widely utilized in photonics and gadgets. PPI-DLW utilizes two bars, one to energize the substrate and cause polymerization, and the other to hinder and extinguish the excitation at the edges. The limit is restricted in certain frameworks, which can be worked on through multifocal exhibits. Nonetheless, determining these bars requires both time and memory.

Recently, a group of scientists from Zhejiang University developed an equal fringe photoinhibition lithography (P3L) framework that can achieve higher proficiency nanoscale creation. Their work is distributed in Cutting Edge Photonics.

“The P3L framework utilizes two channels, which permits the execution of various printing errands and grants the framework the ability to create profoundly complex designs with various periodicities,” says senior creator Xu Liu.

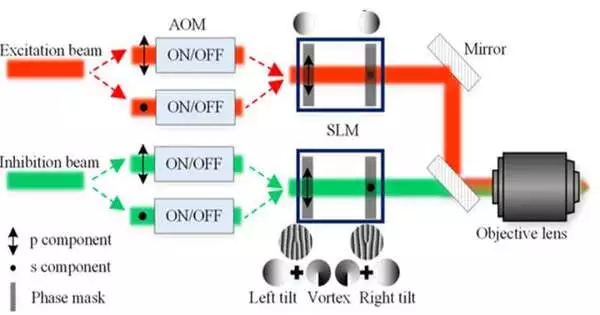

The P3L framework is made up of eight modules in total. The framework begins with two printing channels, each with an excitation strong point and a donut-shaped hindrance bar. The two bars are first settled before being divided into two sub-radiates via a polarization channel. This allows the user to manipulate each sub-bar through an acoustic-optical modulator. The excitation and hindrance radiates are then recovered by recombining the two sub-radiates. The bars are then manipulated using spatial light modulators. Finally, the two bars are connected and sent through a magnifying lens before being centered around the substrate as two spots.

“The P3L system employs two channels, allowing for the execution of various printing tasks and the fabrication of very complex structures with varying periodicities.”

Senior author Xu Liu.

The singular control of each sub-bar permits the printing of nonperiodic and complex examples all the while, without settling on checking speed, thus multiplying the proficiency of the framework. Changing the position and division of the two spots is simple. These elements make the proposed framework more adaptable and useful than regular frameworks with uniform center control.

The scientists confirmed the possibility and capability of the framework by creating an assortment of nanostructures. They initially created a 2D, sub-40 nm nanowire. A sub-20 nm-thick suspended nanowire was created too. From that point onward, the analysts made two lines of letter-set designs by printing dabs that were 200 nm apart. At last, they created 3D designs, including nonperiodic cubic edges, hexagonal lattices, wire structures, and round models, all showing an uncommon goal.

The indistinguishable on-off control of each center builds the adaptability of the framework and permits the fast creation of intricate, nonperiodic examples and designs. The equal-checking element of the framework likewise lessens the time expected to create huge scope, complex designs, and examples. Besides, the new P3L framework achieves a lithography proficiency that is two times greater than that of regular frameworks, whether or not the design is uniform or complex.

Examining the future capability of the work, Xu Liu says, “Multifocus equal checking and PPI can beat the ongoing difficulties in DLW optical creation and upgrade the manufacture of blasted gratings, microlens exhibits, microfluidic structures, and metasurfaces.” The proposed framework could, besides, work with the acknowledgement of “compact, high-goal, high-throughput DLW.”

In view of these outcomes, the proposed P3L framework will obviously act as a helpful device for the improvement of many fields that utilize nanotechnology.

More information: Dazhao Zhu et al, Direct laser writing breaking diffraction barrier based on two-focus parallel peripheral-photoinhibition lithography, Advanced Photonics (2022). DOI: 10.1117/1.AP.4.6.066002