Aluminum-ion batteries are regarded as a promising alternative to conventional batteries that make use of lithium, a scarce and challenging-to-recycle raw material. This is due to the fact that aluminum is one of the most prevalent elements in the crust of the earth, is simpler to recycle, and is safer and less expensive than lithium. However, due to a lack of suitable electrode materials with sufficient storage capacity, the development of such aluminum-ion batteries is still in its infancy.

A positive electrode material made of an organic redox polymer based on phenothiazine has now been developed by a research team led by Gauthier Studer, Prof. Dr. Birgit Esser of the University of Ulm, Prof. Dr. Ingo Krossing, and Prof. Dr. Anna Fischer of the University of Freiburg. In the trial, aluminum batteries with this cathode material put away a formerly unattained limit of 167 milliampere hours for every gram (mAh/g). As a result, the capacity of the organic redox polymer is greater than that of graphite, which has so far primarily served as an electrode material in batteries. The outcomes are distributed in the journal Energy and Natural Science.

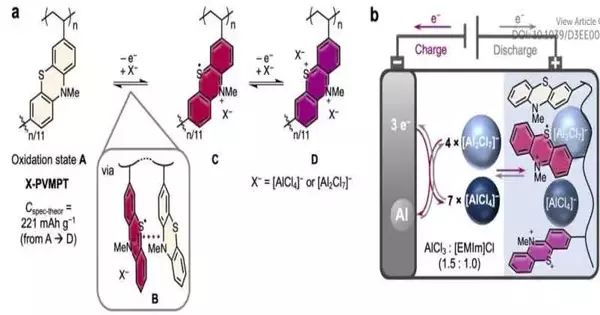

“Our primary goal is to create new organic redox-active materials with high performance and reversibility. We made a big advance by demonstrating for the first time a reversible two-electron redox process for a phenothiazine-based electrode material by examining the redox characteristics of poly(3-vinyl-N-methylphenothiazine) in chloroaluminate-based ionic liquid.”

Gauthier Studer and led by Prof. Dr. Birgit Esser of the University of Ulm

Complex aluminate anions are incorporated into the electrode material as a result of the material’s oxidation during battery charging. Along these lines, the natural redox polymer poly(3-vinyl-N-methylphenothiazine) figures out how to embed two [AlCl4] anions reversibly during charging. The scientists utilized the ionic fluid ethylmethylimidazolium chloride as an electrolyte with added aluminum chloride.

According to Gauthier Studer, “the study of aluminum batteries is an exciting field of research with great potential for future energy storage systems.” Our emphasis lies on growing new natural redox-dynamic materials that show elite execution and reversible properties. By concentrating on the redox properties of poly(3-vinyl-N-methylphenothiazine) in chloroaluminate-based ionic fluid, we have made a huge leap forward by exhibiting an interesting reversible two-electron redox process for a phenothiazine-based cathode material.”

Poly(3-vinyl-N-methylphenothiazine) stores the [AlCl4] anions at possibilities of 0.81 and 1.65 volts and gives explicit limits of up to 167 mAh/g. Graphite, on the other hand, has a discharge capacity of 120 mAh/g when used as an electrode material in aluminum batteries. The battery that the research team presented still has 88% of its capacity after 5,000 charge cycles at 10 C, or a charge and discharge rate of six minutes. The battery returns to its original capacities unchanged at a lower C rate or longer charge and discharge intervals.

According to Birgit Esser, “the electrode material represents a major advance in the development of rechargeable aluminum batteries and thus of advanced and affordable energy storage solutions” because of its high discharge voltage, specific capacity, and excellent capacity retention at fast C rates.

More information: Gauthier Studer et al, On a high-capacity aluminium battery with a two-electron phenothiazine redox polymer as positive electrode, Energy & Environmental Science (2023). DOI: 10.1039/D3EE00235G