Dr. Amir Asadi, an associate teacher in the Branch of Designing Innovation and Modern Circulation at Texas A&M College, is taking noteworthy steps in the field of composite materials. His examination investigates installing designed nanostructures made out of various materials into elite execution composites to accomplish the ideal multifunctionality without forfeiting some other properties. This could prompt progressions in different fields, including hardware, energy capacity, transportation, and purchaser items.

Asadi’s work has critical ramifications, as it tends to the test of simultaneously upgrading two properties—mmultifunctionality and underlying uprightness—iin composite materials, which comprise no less than two materials with various properties. By consolidating designed nanostructures, he expects to beat the compromise commonly seen between these properties, eliminating the need to forfeit one to further develop the other in current assembling techniques. The work is distributed in the diary, Progressed Materials.

He makes sense of, “As of now, fabricating materials with simultaneously expanded usefulness and underlying execution is viewed as confusing. For instance, expanding electrical conductivity frequently lessens strength, or the other way around; expanding strength generally diminishes break durability.”

“We developed a new spray technique called supercritical-CO2 assisted atomization that takes advantage of the properties of supercritical CO2 and its high dissolution in water to create several small droplets inside a suspension of water and nanomaterials,”

Dr. Dorrin Jarrahbashi, co-author of the group’s journal article,

Notwithstanding, Asadi draws motivation from regular designs, for example, the elephant trunk, which has apparently contrary properties and usefulness.

“Regular designs with properties considered contrary in the present design as of now exist, for example, an elephant trunk that is simultaneously solid and solid yet additionally adaptable and fragile to deal with little vegetables while having correspondence and detecting functionalities, all emerging from its strong hydrostat engineering.”

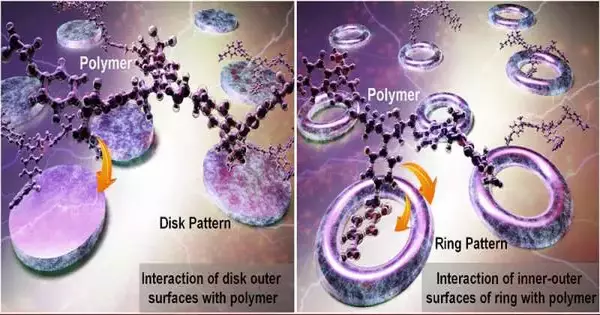

The examination group utilized an exceptional technique to change how much a material retains or repulses water, known as the amphiphilicity degree, in various nanomaterials. Utilizing these materials, they made and joined explicit examples called ring and circle designs, which administer the last properties of composite materials.

To do this, they utilized an exact shower framework with carbon dioxide (CO2) to store the examples on the outer layer of carbon filaments. This permitted them to control the size of the drops, the examples for a minuscule scope, and the materials’ cooperation, at last accomplishing the ideal properties. In this review, water beads conveyed the nanomaterials to the outer layer of carbon strands using the splash framework.

“We fostered another splash strategy, alluded to assupercritical CO2-hhelped atomization, which uses the properties of supercritical CO2 and high disintegration in water to make a few little drops inside a suspension containing water and nanomaterials,” said Dr. Dorrin Jarrahbashi, co-writer of the gathering’s diary article, “Multifunctionality Through Implanting Designed Nanostructures in Superior Execution Composites.”

“Dissimilar to traditional methodologies in which materials with desired characteristic properties are coordinated to add usefulness, this exploration presents the idea of coordinating nanopatterns and shows that various examples from a similar material will prompt various properties in macroscale composites,” Asadi said. “In the event that simultaneous improvement of usefulness and underlying properties is the objective, examples can be consolidated and synergistically upgraded for every single wanted property.”

There are different advantages to Asadi’s methodology. It offers a reasonable, versatile, and financially feasible strategy for making nanostructured materials and parts with tunable properties. The utilization of different materials and exact control over engineering at various length scales improves the flexibility and customization capability of the composites.

As exploration advances, Asadi’s work will probably change the assembly of elite execution composites.

The possible effect of this examination reaches beyond established researchers. “Exploration holds the guarantee of affecting lives,” Asadi expressed. “The presented straightforward yet adaptable procedure will lessen the last expense of mind-boggling and complex gadgets and widen the assembly of nanostructured composites, adding to the U.S. economy and job market. This could bring about superior gadgets, more effective energy frameworks, and imaginative items that improve regular daily existence.”

More information: Ozge Kaynan et al, Multifunctionality through Embedding Patterned Nanostructures in High‐Performance Composites, Advanced Materials (2023). DOI: 10.1002/adma.202300948