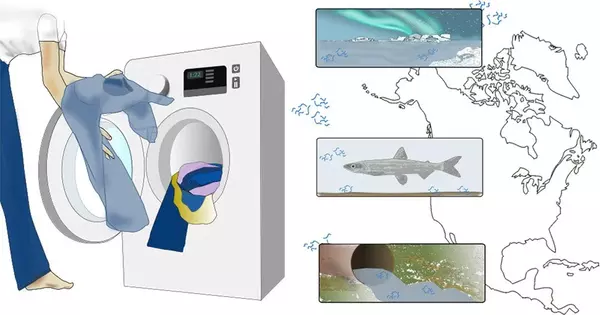

Although it is commonly known that washing clothes releases a huge amount of microfibers into the wastewater, it is unknown whether drying garments has any environmental consequences. According to a pilot study conducted by the City University of Hong Kong (CityU), a single clothes dryer can produce up to 120 million microfibers per year, which is 1.4 to 40 times the amount produced by washing machines. The team recommended that additional filtration systems for dryer vents be implemented as soon as feasible to control the emission of these dangerous airborne microfibers.

The research team was directed by Dr. Zhang Kai, a former research associate at CityU’s State Key Laboratory of Marine Pollution (SKLMP), and Professor Leung Mei-yee, Director of SKLMP and Chair Professor at CityU’s Department of Chemistry. The study, which was published in the scholarly journal Environmental Science & Technology Letters, was on the topic of “Microfibers emitted into the air from a residential tumble dryer.”

Microfiber air pollution is a problem that needs to be addressed.

Microplastics are becoming a bigger problem for aquatic animals and ecosystems. Microfibers have been discovered in air and terrestrial ecosystems, in addition to marine and freshwater habitats. Microplastics in the air have been linked to a variety of health problems, including chronic obstructive pulmonary disease.

Polyester fibers, for example, are commonly used in garments. However, most published research has concentrated on the creation of microfibers from washing machines, with few investigations into the release of textile-associated microfibers into the environment. So Dr. Zhang, Professor Leung, and their study team conducted studies to find out the solution.

“Microfibers released into the air from a household tumble dryer.”

Dr. Zhang Kai

Tumble dryers pollute the air with microfibers.

CityU researchers confirmed the idea that domestic tumble driers emit a considerable amount of plastic microfibers, making them one of the primary contributors of microfiber pollution in the atmosphere in their study.

In their experiment, the researchers dried garments composed of polyester and cotton separately in a tumble dryer with a vent pipe to the outside. They collected and counted the airborne particles that exited the vent while the machine ran for 15 minutes. The findings revealed that both types of clothing produced microfibers, which the team attributed to friction caused by clothes touching together as they tumbled around.

During 15 minutes of use, the dryer released up to 561,810 microfibers. The dryer emitted between 1.4 and 40 times more tiny pieces of both textiles than washing machines observed in prior research for the same number of garments. The release of polyester microfibers increased as the weight of the clothing in the dryer rose, whereas the release of cotton microfibers remained constant regardless of weight.

According to the research team, between 90 and 120 million microfibers are created and emitted into the outside air by a Canadian household’s dryer every year, according to the research.

The discharge of a considerable number of microfibers into the atmosphere from synthetic fabrics in tumble dryers is a worry since they can be irritating if ingested or breathed in and can travel long distances by wind. They can also adsorb and transfer contaminants over great distances.

Tumble dryers should have filtration devices installed.

Previous research has found that while microfibers are emitted from clothes washers into laundry water, this wastewater is frequently treated, eliminating some or all of the fibers before being discharged into rivers, streams, or coastal waterways. Air from dryers, on the other hand, is typically routed via a basic lint filter and a duct before being vented straight to the outdoors.

To reduce air pollution produced by microfibers, the researchers proposed that the emission of microfibers from tumble dryers be minimized in any way possible. In the long run, it is critical to develop better textiles that are more wear-resistant, durable, and environmentally friendly. However, until better replacements for synthetic fibers such as polyester become available, we may reduce the discharge of microfibers from tumble dryers by installing simple, engineered filtration devices at the end of the emission pipelines, “Dr. Zhang advised.

CityU scientists have already created revolutionary filters that prevent microplastics from being spread from washing machines using 3D printing, and they are in the process of developing a similar system for tumble dryers. Improvements in lint filters with smaller mesh sizes and an additional filtration system should be fitted to dryer vents to control the discharge of these airborne microfibers, Professor Leung added.