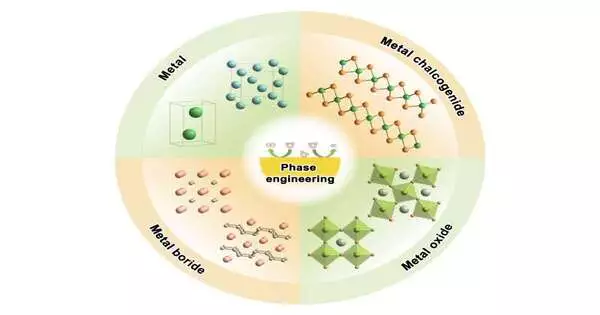

Nuclear revamp changes a material’s physical and chemical properties, which might prompt likely applications across disciplines, remembering for feasible energy. With twenty years of zeroed-in consideration on how managing such revisions—a cycle called stage designing—may empower feasible energy change processes, scientists in China have summed up the work up to this point, including how the field could advance.

They distributed their survey on July 11 in Nano Research, with a particular spotlight on electrocatalysts. These materials trigger, upgrade or resolve the compound and electrical responses engaged in changing energy into storable or usable arrangements. They frequently act as a cathode or as a terminal part.

“Stage designing is a significant system for planning effective electrocatalysts toward these energy changes since it empowers all chemically dynamic iotas to revamp and frame new grids,” said co-relative creator Xiaoxin Zou, teacher, State Key Laboratory of Inorganic Synthesis and Preparative Chemistry, College of Chemistry, Jilin University. “This gives an incredible chance to sanely control iotas to find alluring primary systems and to accomplish better electrocatalysis.” And keeping in mind that, lately, a few scientists have summed up the planning of nanomaterials with novel plans, this is the main precise survey toward excusing how these stages impact electrocatalytic action. “

“Phase engineering is a key method for building efficient electrocatalysts for these energy conversions because it allows all catalytically active atoms to rearrange and form new lattices,”

Xiaoxin Zou,

These different nuclear plans are known as “gem stages.” By changing how the iotas are organized on the outer layer of a strong material or in its mass, one can radically change what the material can do. Zou noted, in any case, that the surface is basically an expansion of the mass and can’t exist freely, so their association is vital to creating alluring and stable electrocatalysts.

“The basic rationale of stage design lies in a close connection between the properties of the surface and the heft of an impetus,” Zou said. “Designing the mass period of an impetus, which straightforwardly impacts the surface, is a strong system to configure savvy impetuses both inside and remotely.”

The gem design of the mass decides the material’s electronic construction, its conductivity, and, generally, the piece of the surface layer. Different mass gem structures have various qualities and surface energies, prompting assorted morphology and chemically dynamic locales. In any event, for impetuses that experience huge surface harm or remaking during the catalysis cycle, Zou said, the mass’ underlying gem structure firmly impacts reconstitution and the last design of the surface.

Throughout recent years, a few scientists have examined this relationship, investigating unusual electrocatalytic stages and how to prompt such changes. Driven by the interest in feasible energy change processes, for example, nitrogen obsession and carbon dioxide decrease, analysts progressed portrayal methods, as well as the hypothesis of basic trial work.

“These things enabled us to precisely and precisely comprehend the impacts of gem stages on electrocatalytic execution,” Zou explained.”Thus, the time has come to sum up stage design related research that unwinds work execution connections and refines forecasts in electrocatalysis studies.”

Then, Zou and his group suggest that analysts seek out four primary regions for additional development gem stage designing for catalysis research.

“To foster able impetuses for various energy change processes from a stage center, we propose investigating the connection between the gem stage and reactant action levels; joining stage designing with other planning systems; unwinding the development and development components of unusual stages; and enhancing synergist exploration of additional liquid stages,” Zou said.

More information: Hui Chen et al, Crystal phase engineering of electrocatalysts for energy conversions, Nano Research (2022). DOI: 10.1007/s12274-022-4605-y