Teacher Wei Xiong’s gathering, from the Wuhan Public Lab for Optoelectronics at Huazhong College of Science and Innovation, proposes a spearheading high-velocity multi-photon polymerization lithography procedure with a record-high 3D printing pace of 7.6 × 107 voxel s1, which is almost one significant degree higher than prior filtering multiphoton lithography (MPL).

Distributed in the Global Diary of Outrageous Assembling (IJEM), this innovation, in view of acousto-optic examining with spatial-exchanging (AOSS), not only prints complex 3D miniature nanostructures with an exactness of 212 nm, yet in addition accomplishes an uncommon 3D printing pace of 7.6 × 107 voxel/s. It resembles a craftsman laying out a self-representation in only five minutes, where each unpredictable detail, down to each strand of hair, comes distinctively to life.

“Handling pace and handling precision are significant execution boundaries for assessing miniature nano-three-layered printing innovation, and this innovation has amazing execution from both viewpoints,” said Prof. Wei Xiong. “This exploration gives a possible specialized course to accomplishing enormous-scope nano-3D imprinting from now on.”

“Handling pace and handling precision are significant execution boundaries for assessing miniature nano three-layered printing innovation, and this innovation has magnificent execution in the two viewpoints,”

Professor Wei Xiong’s group, from the Wuhan National Laboratory for Optoelectronics at Huazhong University of Science and Technology,

The accuracy of the assembly of many-sided and complex three-layered miniature nanostructures fills in as a central foundation for various very front disciplines. Considering its inborn limit with regards to genuine three-layered computerized creation and nanoscale handling goal past as far as possible, two-photon lithography (TPL) has reliably stayed a point of convergence of examination inside the field.

It has now found broad applications in state-of-the-art spaces, including three-layered metamaterials, miniature optical and microelectronic parts, and biomedical design.

Notwithstanding, regardless of its high nanoscale goal capacities, the restricted handling rate of TPL has relentlessly compelled its true capacity. For instance, the printing of a basic coin can frequently take more than a few hours, a time span obviously lacking for modern creation applications.

Then, at that point, Jiao started a progression of exploratory investigations and ultimately found the acousto-optic redirector (AOD) as the highlight of the interaction to speed up.

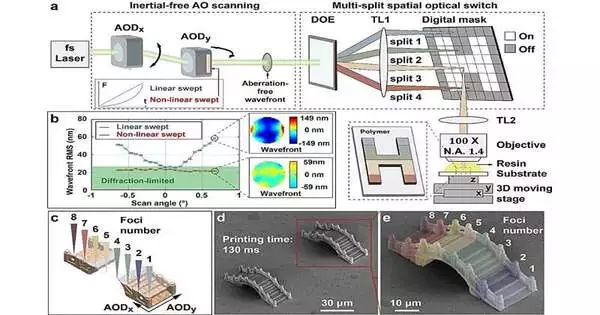

Conventional examination-based TPL utilizes mechanical filtering strategies like galvanometric mirrors, yet their checking speed is limited by idleness. Conversely, the acousto-optic diverter (AOD) can accomplish this without inertial acousto-optic examination, bringing about a critical progression in speed.

“The movement of a moving vehicle normally incorporates consecutive activities, for example, slowing down, pivoting, and resulting speed increase, which intrinsically consumes a significant measure of time because of the impact of idleness,” said Binzhang Jiao (Ph.D. 22), the principal creator of the paper.

A galvanometer with dormancy is very much like a vehicle, where speed increase and deceleration processes are tedious. Then again, AOD isn’t compelled by idleness since it depends on sound waves for checking. Contrasted with conventional mechanical mirror checking, this approach has yielded a 5- to 20-fold expansion in laser filtering speed.

Jiao has effectively fostered a nonlinear sign tweak procedure for the AOD, guaranteeing the spot size approximates as far as possible during fast acousto-optic checking. Simultaneously, the reconciliation of diffractive optical components (DOE) has empowered multi-central equal acousto-optic examination, further improving handling throughput. The spatial districts of the multi-central spots are freely constrained by the spatial optical switch, empowering the manufacture of non-occasional designs.

They exhibited an eight-point convergence Multiphoton Lithography (MPL) framework, achieving a voxel size of 212 nm and a voxel printing pace of 7.6 × 107 voxel/s.

“Numerous central focuses can be printed independently, as though one individual had eight hands,” said Jiao. This voxel printing rate is 8.4 times quicker than the quickest precisely filtered MPL technique detailed previously and multiple times quicker than the quickest diffractive-checked MPL strategy announced. When contrasted with popularized MPL strategies, the printing rate of this strategy can be improved by up to multiple times.

Despite the fact that it is still quite far to go from labs to production lines, the group communicates confidence about the eventual fate of AOSS. “To increment the acousto-optic examining range, the checking point of the acousto-optic filtering can be expanded from here on out. In like manner, a higher acousto-optic examining speed and an expanded number of foci can keep on expanding the throughput of AOSS,” said Prof. Wei Xiong.

More information: Binzhang Jiao Jiao et al., Acousto-optic scanning spatial-switching multiphoton lithography, International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/ace0a7