A counterintuitive method for strengthening polymers has been discovered by a group of MIT and Duke University chemists: introduce some bonds that are weaker into the material.

Working with a sort of polymer known as polyacrylate elastomers, the scientists found that they could expand the materials’ protection from destruction by ten times just by utilizing a more fragile kind of crosslinker to join a portion of the polymer building blocks.

These polymers that look like rubber are often used in car parts and as the “ink” for 3D-printed objects. The researchers are currently looking into whether or not this method could be applied to additional materials, like rubber tires.

“Polymer engineers understand how to make materials tougher, but it always involves changing another property of the material that you don’t want to change. In this case, the toughness improvement occurs without any other significant change in physical properties—at least that we can measure—and is achieved by replacing only a small fraction of the overall material.”

Stephen Craig, a professor of chemistry at Duke University.

Jeremiah Johnson, a chemistry professor at MIT and one of the study’s senior authors, states, “If you could make a rubber tire 10 times more resistant to tearing, that could have a dramatic impact on the tire’s lifetime and on the amount of microplastic waste that breaks off.”

A huge benefit of this approach is that it doesn’t seem to change any of the other actual properties of the polymers.

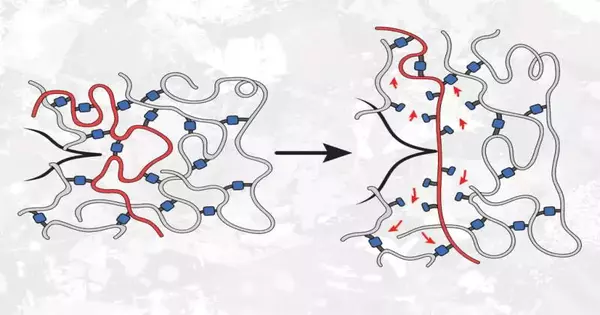

Two rubbery elastomers made with conventional and mechanophore crosslinkers are shown on the left. Except for the fact that the one on the left is much more difficult to tear due to the embedded mechanophores, the properties of the two are identical. Credit: “Polymer engineers know how to make materials tougher, but doing so always requires changing a property of the material that you don’t want to change,” says Shu Wang. Here, the strength upgrade comes with practically no other massive change in actual properties—basically that we can quantify—and it is achieved through the substitution of just a little part of the general material,” says Stephen Craig, a teacher of science at Duke College who is likewise a senior creator of the paper.

Johnson, Craig, and Duke University Professor Michael Rubinstein, who is also a senior author of the paper, have worked together for a long time on this project. Shu Wang, a postdoc at MIT who received his Ph.D. from Duke, is the paper’s lead author.

The weakest link

Polyacrylate elastomers are the weakest link in a polymer network made of acrylate strands linked by molecules. Materials with various properties can be created by joining these building blocks together in various ways.

A star polymer network is one architecture that is frequently utilized for these polymers. There are two types of building blocks that go into these polymers: one consists of a star with four identical arms, and the other is a linker chain. A network resembling a volleyball net is created when these linkers attach themselves to the ends of each star’s arms.

Craig, Rubinstein, and MIT Professor Bradley Olsen collaborated to measure these polymers’ strength in a 2021 study. As was to be expected, they discovered that the material became weaker when weaker end-linkers were used to hold the polymer strands together. Cyclobutane-containing weaker linkers, which are made of cyclic molecules, can be broken with much less force than the linkers that are typically used to join these building blocks.

The researchers decided to investigate a different kind of polymer network as a follow-up to that one. In this type of network, polymer strands are cross-linked to other strands at random locations rather than joining at the ends.

This time, the material became significantly more resistant to tearing when the researchers used weaker linkers to join the acrylate building blocks together.

The researchers hypothesize that the reason for this is that, rather than being a part of the ultimate strands themselves, the weaker bonds are instead randomly distributed throughout the material as junctions between otherwise strong strands. When this material is stretched to its breaking point, any cracks that are spreading through it try to go through the weaker bonds instead of the stronger ones. Because of this, the crack must break more bonds than if all of the bonds were of the same strength.

According to Johnson, “Even though those bonds are weaker, more of them end up having to be broken because the crack takes a path through the weakest bonds, which ends up being a longer path.”

Tough materials

Using this method, the researchers demonstrated that polyacrylates made with stronger crosslinking molecules were nine to ten times more difficult to tear than polyacrylates made with weaker linkers. Even when the material’s weak crosslinkers made up only about 2% of the total, this effect was still achieved.

The researchers also demonstrated that the material’s other properties, such as its resistance to breakdown when heated, were unaffected by the altered composition.

According to Johnson, “it is quite rare for two materials to have an almost order of magnitude difference in tearing” despite sharing the same network structure and properties.

The specialists are currently exploring whether this approach could be utilized to work on the durability of different materials, including elastic.

More information: Shu Wang et al, Facile mechanochemical cycloreversion of polymer cross-linkers enhances tear resistance, Science (2023). DOI: 10.1126/science.adg3229.