To improve biomaterials for dependable, practical paper creation, building development, and biofuel advancement, specialists frequently concentrate on the construction of plant cells by utilizing methods like freezing plant cells or putting them in a vacuum. These techniques give important information, but frequently make extremely durable examples.

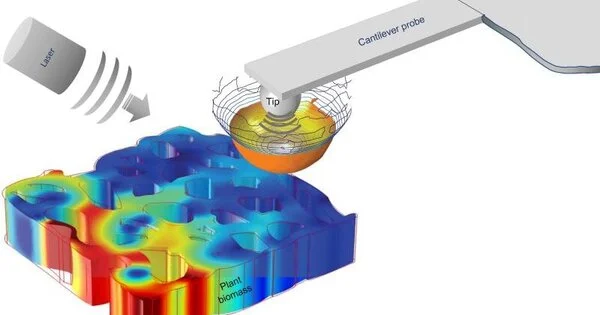

A group of physicists, including Ali Passian, an exploration researcher at the Department of Energy’s Oak Ridge National Laboratory, and specialists from the French National Center for Scientific Research, or CNRS, utilized best-in-class microscopy and spectroscopy strategies to give nondestructive other options. Utilizing a procedure called dispersing type checking close field optical microscopy, the group inspected the organization of cell dividers from youthful poplar trees without harming the examples.

In any case, the group actually had different impediments to surviving. Despite the fact that plant cell dividers are notoriously hard to explore because of the presence of perplexing polymers like microfibrils (slight strings of biomass that Passian depicts as a labyrinth of interwoven spaghetti strings), the group arrived at a goal of better than 20 nanometers, or multiple times less than a strand of human hair. This itemized view enabled the scientists to recognize optical properties of plant cell materials in fascinating ways across vast and small areas, even down to the width of a single microfibril.Their outcomes were distributed in communications materials.

“Our technique enabled us to examine the sample’s morphological, optical and chemical properties at the nanometric scale—all within the same measurement,”

Ali Passian, a research scientist at the Department of Energy

“Our strategy permitted us to take a gander at the example’s morphology and optical and substance properties at the nanometric scale—all within a similar estimation,” Passian said.

Alongside ORNL and CNRS, the group included scientists from Aix-Marseille University, the Interdisciplinary Nanoscience Center of Marseille, the Fresnel Institute, and Germany’s Neaspec GmbH.

“Until recently, these optical properties were estimated in situ only from extricated parts, which don’t give data in that frame of mind of underlying and substance properties,” Fresnel Institute analyst Aude Lereu said.

By utilizing their estimation strategy to get a progression of nitty-gritty pictures in a single locale of the poplar wood cell divider, the group likewise noticed the dissemination of underlying polymers, for example, lignin and cellulose, which are hard substances that act as the “bones” of natural frameworks and can be extricated and changed over into biofuels and bioproducts.

This information could be utilized to further develop synthetic medicines that utilize acids or proteins to increase polymer yields and forestall biomaterials from corrupting when presented to outer elements like growth or stickiness. Since the poplar trees had previously experienced a delignification cycle, the specialists had the option to pinpoint both innocuous and possibly destructive compositional changes.

“While modifying a material, it’s critical to screen precisely the way that it changes at the sub-atomic level,” Passian said. “By applying our method to a pretreated poplar tree example, we had the option to concentrate on the example while monitoring any progressions that could influence its suitability.”

The scientists chose poplar as a delegate framework on the grounds that these trees develop rapidly and require little support. However, the method utilized on poplar could give correspondingly nitty-gritty information on numerous different plants, which specialists could use to work on the proficiency of medicines and design ideal biomaterials.

“Our method uncovered that a few sorts of lignin were not completely taken out during delignification, and this information could assist with streamlining the cycle and add to a superior understanding of lignin stubbornness,” Lereu said.

The strategy could also be useful to the field of added substance assembling, or 3D printing, which includes stacking layers of materials to make a wide assortment of items, from counterfeit fish to rocket parts. During the printing system, which Passian depicts as a more complicated form of channeling frosting onto a cake with a baked good sack, the estimation procedure could add a layer of value control to limit human blunders, right material conveyance, and eliminate any impurities continuously.

Acquiring a fantastic view of unobtrusive changes in plant cells represented a test. However, Passian guesses that integrating quantum-mechanical standards into microscopy examinations could permit scientists to get a significantly closer view without harming fragile natural examples.

“Not too far off, quantum science could assist with bypassing the obstructions of traditional procedures to additionally work on the goal of these estimations,” he said.

More information: Anne M. Charrier et al, In situ plant materials hyperspectral imaging by multimodal scattering near-field optical microscopy, Communications Materials (2021). DOI: 10.1038/s43246-021-00166-7