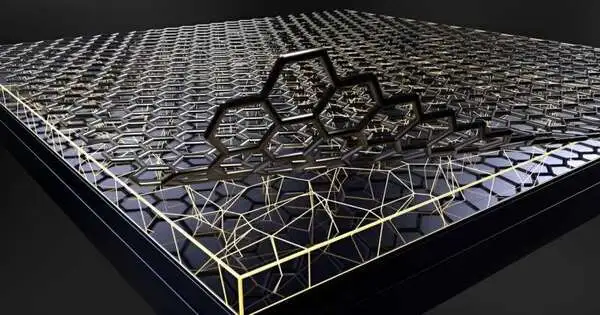

Specialists have shown that treated steel and other metal compounds covered with hexagonal boron nitride, or hBN, display non-stick or low-erosion characteristics while also working on long-term assurance against brutal consumption and high-temperature oxidation in air. The work has been distributed at cutting-edge material connection points.

Metal composites—combinations of at least two metals—are made to have major areas of strength and are impervious to erosion or oxidation. By adding coatings, or “defensive layers,” to make those materials much harder, researchers could upgrade existing items and empower the production of new, inventive ones.

For instance, reinforcing may help the capacity of sunlight-based chargers to increase intensity and oppose ecological variables. Moreover, it permits semiconductors to keep up with legitimate working temperatures and aviation turbine edges to make preparations for wear, diminish rubbing, and endure hot circumstances.

The hBN coatings are delivered from a mix of strong boron sources and sub-atomic nitrogen by utilizing a cycle called climatic strain compound fume testimony.

“This amalgamation method tends to address adaptability issues, for example, cost and cycle wellbeing in applications where those perspectives have been tricky,” said ORNL’s Ivan Vlassiouk, who drove the review. “Other than giving a flexible defensive layer to prepares and metals, utilizing this cycle to orchestrate single-and hardly any layer hBN for arising two-layered electronic and photonic gadgets could work on their presentation.”

More information: Ivan Vlassiouk et al, Armor for Steel: Facile Synthesis of Hexagonal Boron Nitride Films on Various Substrates, Advanced Materials Interfaces (2023). DOI: 10.1002/admi.202300704