Researchers created a single-material, single-stimulus microstructure that can outmaneuver even biological cilia. These programmable, micron-scale structures might be used for a variety of applications, including soft robotics, biocompatible medical devices, and even dynamic information encryption.

For years, scientists have been striving to create small, artificial cilia for minuscule robotic systems capable of performing complex actions such as bending, twisting, and reversing. Building these smaller-than-a-human-hair microstructures often requires multi-step production techniques and varied stimuli to induce the intricate movements, limiting their wide-scale uses.

Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) researchers have built a single-material, single-stimulus microstructure that can outmaneuver even living cilia. These programmable, micron-scale structures might be used for a variety of applications, including soft robotics, biocompatible medical devices, and even dynamic information encryption.

The research is published in Nature.

Cilia are hair-like tiny structures found throughout our bodies that provide motion at the tiniest scales. They carry out a variety of key actions that are essential for our bodies to function normally. A range of disorders known together as ciliopathies occur from abnormal cilia activity. The goal of artificially replicating cilia is to better understand their normal/abnormal functionality and to create cilia-inspired micro/nanoengineering devices.

Innovations in adaptive self-regulated materials capable of a diverse set of programmed motions represent a very active field that is being tackled by interdisciplinary teams of scientists and engineers.

Joanna Aizenberg

“Innovations in adaptive self-regulated materials capable of a diverse set of programmed motions represent a very active field that is being tackled by interdisciplinary teams of scientists and engineers,” said Joanna Aizenberg, Amy Smith Berylson Professor of Materials Science and Professor of Chemistry & Chemical Biology at SEAS and the paper’s senior author. “Advances in this discipline may have a considerable impact on how we build materials and devices for a wide range of applications, including robotics, medicine, and information technology.”

Unlike prior studies, which relied on complex multi-component materials to enable programmable movement of reconfigurable structural elements, Aizenberg and her colleagues created a microstructure pillar out of a single material: a photoresponsive liquid crystal elastomer. Because of the way the liquid crystal elastomer’s essential building pieces are placed, when light strikes the microstructure, those building blocks realign and the structure changes shape.

Two things happen as the form changes. First, the area where the light strikes becomes translucent, allowing the light to permeate deeper into the material and cause further deformations. Second, as the material deforms and the shape shifts, a new part of the pillar is exposed to light, causing that area to change shape as well.

This feedback loop propels the microstructure into a stroke-like cycle of motion.

“We have a self-regulating material as a result of this internal and exterior feedback loop. When you switch on the light, it does all of its own work “said Shucong Li, a graduate student in Harvard’s Department of Chemistry and Chemical Biology and the paper’s co-first author.

When the light is turned off, the material returns to its original shape.

The specific twists and motions of the material change with its shape, making these simple structures infinitely reconfigurable and customizable. The researchers illustrated the movements of circular, square, L- and T-shaped, and palm-tree-shaped structures using a model and experiments, and spelled out all the additional ways the material may be modified.

“We demonstrated that we can program the choreography of this dynamic dance by tailoring a variety of parameters such as illumination angle, light intensity, molecular alignment, microstructure geometry, temperature, and irradiation intervals and duration,” said Michael M. Lerch, co-first author of the paper and a postdoctoral fellow in the Aizenberg Lab.

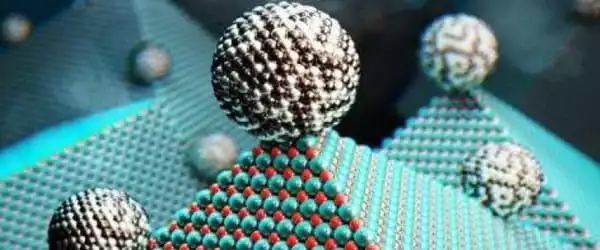

The study team also demonstrated how these pillars interact with each other as part of an array to offer another layer of complexity and utility.

“When these pillars are clustered together, they interact in very intricate ways,” Li explained. “This is because each deforming pillar throws a shadow on its neighbor, which changes throughout the deformation process.” “Programming how these shadow-mediated self-exposures evolve and interact with one another dynamically could be valuable for applications such as dynamic information encryption.”

“The wide design space for individual and collective motions has the potential to alter soft robotics, micro-walkers, sensors, and robust information encryption systems,” Aizenberg added.