In order to deliver substantial designs that can fix their breaks, specialists from Drexel College’s School of Designing are putting another curve on an old stunt for working on the solidity of cement.

Fiber support has been around since the primary bricklayers blended horsehair into their mud. Anyway, the Drexel research group is taking this strategy to a higher level by transforming building-up strands into a living tissue framework that surges concrete-mending microorganisms to the site of breaks to fix the harm.

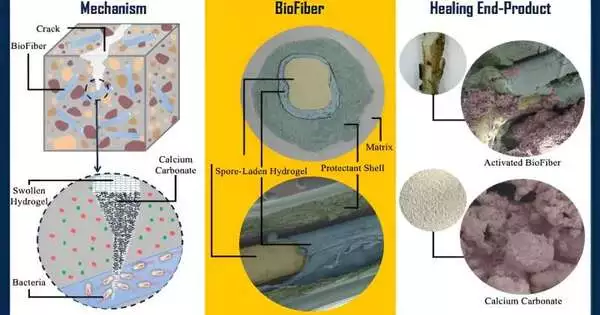

As of late revealed in the diary Development and Building Materials, Drexel’s “BioFiber” is a polymer fiber encased in a microorganism-loaded hydrogel and a defensive, harm-responsive shell. The team says that a grid of BioFibers embedded in a concrete structure can make it more durable, stop cracks from growing, and make it possible for the structure to heal itself.

“Every day, we see damage to our aging concrete structures, which reduces their functional life and necessitates costly critical repairs. Do you think they can heal themselves? Our skin tissue naturally does this through a multilayer fibrous structure infused with our self-healing fluid—blood. This concept is mimicked by these biofibers, which use stone-making bacteria to create damage-responsive living self-healing concrete.”

Amir Farnam, Ph.D., an associate professor in the College of Engineering.

“This is a thrilling improvement for the continuous endeavors to further develop building materials utilizing motivation from nature,” said Amir Farnam, Ph.D., an academic partner in the School of Designing who was the head of the examination group.

“We are seeing each day that our maturing substantial designs are encountering harm, which brings down their practical life and requires basic fixes that are expensive. I imagine they can mend themselves. In our skin, our tissue does it normally through a multi-facet sinewy construction imbued with our self-recuperating liquid—blood. These biofibers copy this idea and utilize stone-production microscopic organisms to make harm-responsive living self-mending concrete.”

Extending the life expectancy of cement isn’t simply an advantage for the structure area; it’s turned into a need for nations all over the planet that are attempting to lessen ozone-harming substances. The most common way of making the elements of cement—consuming a combination of minerals like limestone, dirt, or shale at temperatures greater than 2,000 degrees Fahrenheit—represents 8% of worldwide ozone-harming substance emanations.

Substantial designs can debase in just 50 years, contingent upon their current circumstances. Among substitutes and the developing interest in new structures, concrete is the most consumed and sought-after building material on the planet.

Delivering something substantial that can endure longer would be a major move toward decreasing its commitment to an unnatural weather change and also lessening the drawn-out cost of framework fixes, which is the reason the U.S. Division of Energy has, as of late, sent off endeavors zeroed in on further developing it.

Drexel’s BioFiber framework utilizes a primary element covered in microorganism-loaded hydrogel embodied in a polymer shell to empower self-fixing concrete. Credit: Drexel College

Throughout the past 10 years, Drexel has led the way in taking a gander at how to work on substantial’s supportability and sturdiness, and Farnam’s lab is important for a group partaking in a Branch of Protection work to sustain its maturing structures.

Mohammad Houshmand, a doctoral candidate in Farnam’s lab and the study’s lead author, stated, “The Advanced Infrastructure Materials Lab has nurtured the concept of bio-self-healing cementitious composites for several years.”

“The BioFiber project addresses a cooperative, multidisciplinary approach, incorporating skills from the fields of structural design, science, and materials science. The main goal is to be the first to develop a multifunctional, self-healing BioFiber technology and set new standards at the intersection of these many different fields.”

The group’s way to deal with making BioFibers was motivated by skin tissue’s self-mending ability and the vasculature framework’s part in assisting organic entities with recuperating their own injuries. It utilizes a natural method they created to empower self-fixing in substantial foundations with the assistance of biomineralizing microscopic organisms.

In a joint effort with research groups led by Caroline Schauer, Ph.D., the Margaret C. Consumes Seat in Designing, Christopher Deals, Ph.D., an academic partner, and Ahmad Najafi, Ph.D., an associate teacher, all from the School of Designing, the gathering recognized a kind of Lysinibacillus sphaericus microbes as a bio-recuperating specialist for the fiber.

The solid microscopic organisms, normally tracked down in the dirt, can drive a natural cycle called microbial-prompted calcium carbonate precipitation to make a stone-like material that can balance out and solidify into a fix for uncovered breaks in concrete.

When instigated into shaping an endospore, the microbes can endure the brutal circumstances inside the substance, lying lethargic until called right into it.

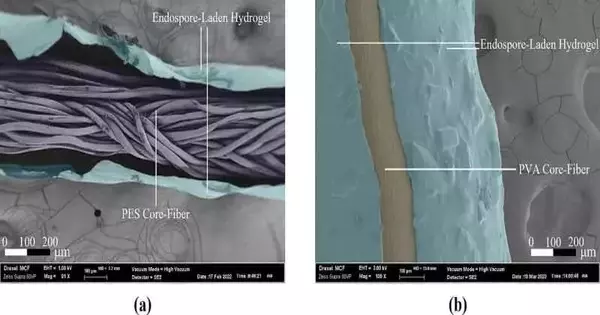

An examining electron tiny picture of Drexel’s BioFiber self-mending substantial framework shows an underlying central element with hydrogel covering and polymer shell. Credit: Drexel University According to Schauer,

“One of the amazing things about this research is how everyone approaches the problem from their different expertise, and the solutions to creating novel biofilms are so much stronger because of that.”

“Choosing the right mix of microorganisms, hydrogel, and polymer covering was integral to this exploration and to the usefulness of BioFiber. Drawing motivation from nature is a certain something, yet making an interpretation of that into an application contained organic fixings that can all coincide in a utilitarian design is very much an endeavor—one that required a multifaced group of specialists to accomplish effectively.”

To gather the BioFiber, the group began with a polymer fiber center fit for settling and supporting substantial designs. It encased the entire assembly in a damage-responsive polymer shell, similar to skin tissues, and coated the fiber with a layer of hydrogel that was loaded with endospores. The whole gathering is a little over a quarter of a millimeter thick.

Put in a lattice all through the substance as it is poured, the BioFiber goes about as a building-up help specialist. However, its true capabilities are only revealed when a crack penetrates the concrete deep enough to penetrate the outer polymer shell of the fiber.

As water advances into the break, at last arriving at the BioFiber, it makes the hydrogel grow and push right out of the shell and up toward the outer layer of the break. While this occurs, the microscopic organisms are enacted from their endospore structure within the sight of carbon and a supplement source in the substantial. Responding to the calcium in the substance, the microorganisms produce calcium carbonate, which goes about as an establishing material to fill the break the entire way to the surface.

The mending time at last relies upon the size of the break and action of the microscopic organisms—a component the group is currently researching—however, early signs recommend the microorganisms could take care of their business in just one to two days.

“While there is a lot of work to be finished in looking at the energy of self-fix, our discoveries propose that this is a suitable technique for capturing development, balancing out, and fixing breaks without outer mediation,” Farnam said. “As a result, BioFiber may one day be utilized to construct a “living” concrete infrastructure and extend its lifespan, avoiding costly replacements or repairs.”

More information: Mohammad Houshmand Khaneghahi et al. Development of a nature-inspired polymeric fiber (BioFiber) for advanced delivery of self-healing agents into concrete, Construction and Building Materials (2023). DOI: 10.1016/j.conbuildmat.2023.133765