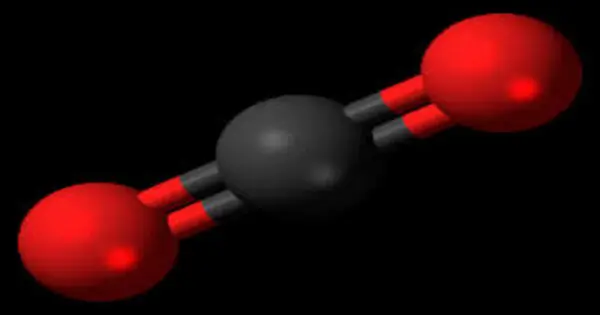

A worldwide group of researchers is utilizing permeable, wipe-like materials that can trap carbon dioxide in their depressions while permitting different gases, for example, nitrogen to pass through.

The materials are produced using sugar and minimally expensive antacid metal salts, so they would be modest enough for enormous scope organization, and they could be especially compelling for restricting the ecological harm of coal-terminated power plants.

“Coal emissions remain the world’s leading source of carbon dioxide emissions, What’s nice about Mary’s work is that she not only discovered a material that’s useful for carbon-dioxide capture from coal flue gas, but she also outlined the structure-property relationships that will allow us to design materials for other applications, such as capturing CO2 from natural gas-fired power plants, as well as possibly even from air, which is one of the really big challenges of our time,”

German Chemical Society. Phillip Milner,

The group’s paper is distributed in Angewandte Chemie, a distribution of the German Chemical Society. Phillip Milner, partner teacher of synthetic and substance science at Cornell University, drove the joint effort.

Throughout the previous 100 years, the main strategy for carbon capture in science has been a cycle known as amine cleaning. Amines are natural, smelling salts that infer that they contain nitrogen. In a watery arrangement, they can specifically eliminate carbon dioxide from gas blends. In any case, oxygen debases them each time they’re cycled, and that implies that increasingly more of the material would have to be delivered, subsequently driving up the expense.

As opposed to attempting to sort out some way to defeat the oxidation issue in amines, Milner’s lab has been exploring different avenues regarding an alternate group of materials and planning them explicitly for carbon dioxide capture.

The new task centers around wipe-like materials containing hydroxide locales in their pores. Ordinarily, arrangements of hydroxide salts reversibly respond to carbon dioxide and structure bicarbonate salts, like baking pop, catching the carbon dioxide. However, to recover the hydroxide salt, the material should be warmed up to 500 to 800 degrees Celsius—no simple accomplishment, and not a modest one, by the same token.

Lead creator and doctoral understudy Mary Zick found that by consolidating heaps of sugar particles called cyclodextrins as a starter and bubbling them with soluble base metal salts in water, she could make a wipe like material that is filled with pits in which carbon dioxide predicaments unequivocally, yet in which different gases, for example, nitrogen go effectively through.

Milner said. “Coal discharges are as yet the No. 1 anthropogenic source of carbon-dioxide emanations on the planet.” “What’s decent about this work is that Mary not just saw carbon dioxide as a material that is helpful for carbon dioxide capture from coal vent gas, yet she framed the construction property connections that will permit us to plan materials for different applications, such as catching CO2 from flammable gas terminated power plants, as well as perhaps from air, which is one of the biggest difficulties in recent memory.”