A space lift, a design interfacing the Earth’s surface to a space station, would take into consideration the expense of productive vehicles of individuals and materials. Regardless, an exceptionally light area of strength is required to make such an innovation a reality.The carbon nanotube is another sort of material that is multiple times more grounded than steel yet multiple times lighter, with copper-like high electrical conductivity and precious stone-like warm conductivity. In any case, past carbon nanotube filaments were not great for broad use, attributable to the little contact region with contiguous carbon nanotubes and the restricted length they had.

An exploration group led by Dr. Bon-Cheol Ku at the Korea Institute of Science and Technology (KIST) Jeonbuk Institute of Advanced Composite Materials in South Korea reported that it had fostered a super high-strength and super high-modulus carbon nanotube fiber material through a joint exploration project with Professor Seongwoo Ryu’s examination group at Suwon University in South Korea and Dr. Juan José Vilatela from the IMDEA Materials Institute in Spain. Their exploration is distributed in Science Advances.

“South Korea, a latecomer to the carbon fiber business, will lead the industry thanks to K-carbon fiber manufacturing technology based on carbon nanotube materials. This critical technology will be the future development engine for the aerospace and defense industries, propelling South Korea into the ranks of material superpowers.”

Dr. Bon-Cheol Ku

Existing polyacrylonitrile (PAN)-based carbon strands have high strength and a low modulus, while pitch-based carbon filaments have low strength and a high modulus. Past investigations into all the while working on the elasticity and modulus of carbon filaments just centered around adding a limited quantity of carbon nanotubes. Nonetheless, the KIST, Suwon University, and IMDEA joint examination group created filaments altogether composed of carbon nanotubes without utilizing the ordinary carbon fiber antecedents, polymer and pitch.

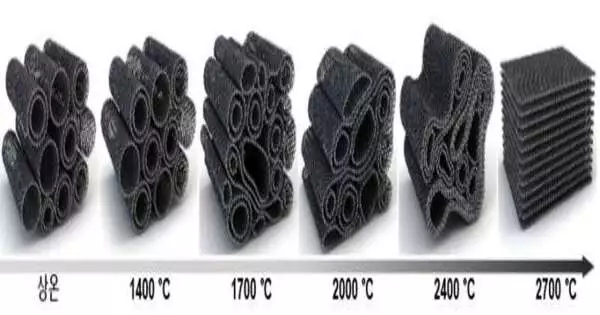

The group made high-thickness, high-arrangement carbon nanotube filaments through a wet-turn fabricating process reasonable for large scale manufacturing and afterward strengthened them at high temperatures to enable their designs to be changed over into different explicit sorts, including graphite. Appropriately, the contact region of the carbon nanotubes expanded. These carbon nanotube strands created in such a manner are supposed to have different applications as they all the while display super high strength (6.57 GPa) and super high modulus (629 GPa) qualities, which couldn’t be accomplished with traditional carbon filaments. The filaments likewise showed high bunch strength, demonstrating adaptability.

Dr. Bon-Cheol Ku said, “K-carbon fiber producing innovation utilizing carbon nanotube materials will empower South Korea, a newbie to the carbon fiber field, to come out on top.” This significant innovation will act as the future development motor for the aviation and protection businesses, which are expected to move South Korea into the domain of materials superpowers. “

“We have gotten the first innovation for assembling carbon nanotube-based super high strength and super high modulus carbon strands. However, for the large scale manufacturing of ultrahigh execution carbon filaments to be conceivable, the large scale manufacturing of twofold walled carbon nanotubes, a center material, should happen first,” he continued, expressing that help on the public level as well as industry interest are expected to additional advancement.

More information: Dongju Lee et al, Ultrahigh strength, modulus, and conductivity of graphitic fibers by macromolecular coalescence, Science Advances (2022). DOI: 10.1126/sciadv.abn0939

Journal information: Science Advances