Scientists set out on a multidisciplinary undertaking to decide how cavitation rising inside miniature or nano-designs could moderate surface disintegration and upgrade the proficiency in microfluidic blending gadgets, frequently used to rapidly and successfully blend numerous examples.

Likely uses of the examination discoveries include the development of more proficient and tough siphoning apparatus and their execution in versatile, high-accuracy natural tests presently saved exclusively for research center settings. The examination was distributed late in logical reports.

The task was driven by Dr. Guillermo Aguilar, James and Ada Forsyth, teachers and office heads in the J. Mike Walker ’66 Division of Mechanical Designing at Texas A&M College.

“This research could also help us better understand and create new technologies like erosion mitigation by surface micropatterning and the development of efficient microfluidic mixing devices.”

Dr. Guillermo Aguilar

Cavitation—tthe quick development and breakdown of fumes rising in a fluid—iis a broadly concentrated field. This undertaking tried to more readily comprehend the essential study of cavitation elements while likewise distinguishing possible applications.

“Despite the fact that cavitation has been widely concentrated, the association of cavitation air pockets and planes with miniature or nanostructures and shockwaves is not yet a functional area of investigation,” Aguilar explained.”This study may likewise assist us with better comprehension and further foster new innovations, for example, disintegration moderation through surface micropatterning and the improvement of effective microfluidic blending gadgets.”

The strategies empowered the group to trap air pockets in a micro structured surface and show how these air pockets could serve to significantly decrease the disintegration ordinarily brought about by cavitation peculiarities systems.

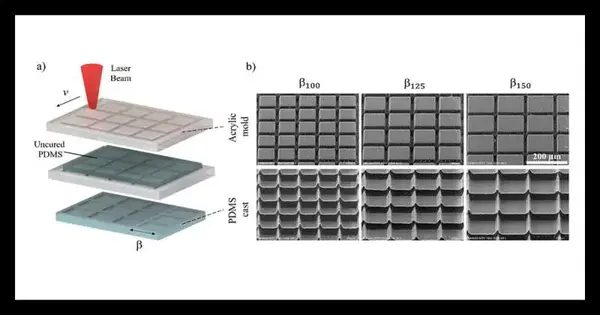

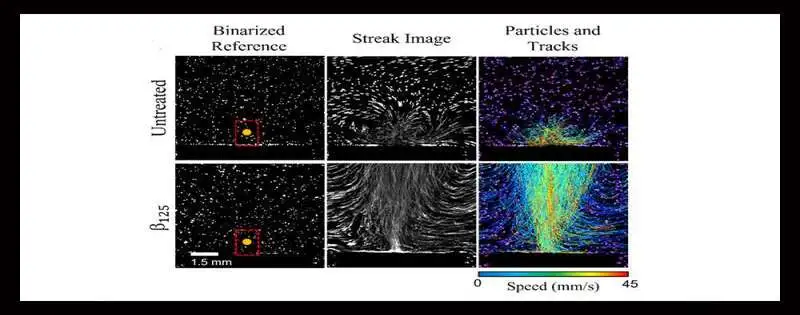

Specialists utilized high-velocity cameras outfitted with magnifying instrument focal points close by laser-instigated cavitation to report the little air pockets, which commonly boast the size of a solitary millimeter and last only one-tenth of a millisecond. Furthermore, the project used a variety of lasers to meet various needs throughout the testing cycle, including a femtosecond laser to create micropatterning on the objective surface, a nanosecond laser to induce cavitation, and a constant wave laser to perform molecule following.

The strategies empowered the group to trap air pockets in a microstructured surface and show how these air pockets could serve to significantly reduce the disintegration normally brought about by cavitation peculiarities components. Simultaneously, cavitation breakdown rises to close miniature, and nano-designed surfaces improved bordering liquid blending.

“We accept that this work can possibly be the beginning stage for creating applications in microfluidics and disintegration moderation,” Aguilar said. Later on, we could have business microfluidic gadgets that utilize this strategy for in-situ, high-accuracy natural tests, which are presently limited to research center conditions. We likewise accept that this strategy can be carried out to permit siphoning apparatus to work all the more proficiently and last longer, which would translate into a cost decrease.

One of the significant difficulties for this undertaking came in the preparation. A large number of mastery in various disciplines was expected while gathering the group—an errand for which Aguilar said mechanical specialists are exceptional.

“This can be portrayed as a multidisciplinary project as it involves liquids as well as optics, photonics, and material science,” Aguilar said. “As mechanical designers, we have a vast knowledge base that allows us to handle complex issues like this.” “Consequently, this sort of multidisciplinary research depends intensely on cooperation.”

More information: Vicente Robles et al, The effect of scalable PDMS gas-entrapping microstructures on the dynamics of a single cavitation bubble, Scientific Reports (2022). DOI: 10.1038/s41598-022-24746-w

Journal information: Scientific Reports